This is the first part that I had to glue multiple foam

pieces together using the hinged method. Surprisingly, this method was quite

easy and worked well. The biggest challenge was to get symmetrical &

consistent rounding inside corners. These corners also have different radii. I

tried wrapping sand paper around various diameter wood dowels without great

success – because I do not have that consistent ‘touch’ from one corner to

another – as a professional carpenter. I ended up with transitional bumps

between the rounded corners to the straight edges. Its’ probably OK,

functionally. However, if I have to look at the imperfection every time I get on

the plane, I’ll hate myself for not doing something about it early on… As a

result, I had a set of angled templates with

rounded corners made, resulting in a nicely

rounded inside corner every time!

Making the vertical stiffeners

was challenging. I followed the ‘plastic wrapped wood strip’ and BID tape

recommendations by others. It was done, but the quality will definitely blow my

Grand Championship Quality Award!

Lessons

learned – BID tape and rounded corner

templates.

In

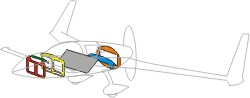

this Chapter, we are going to build various cross members of the aircraft. They

are the Instrument Panel, Seat Back, Landing Gear Bulkheads, Firewall and a

couple front panels namely F22 and F28. Since this is the first chapter,

all the parts are flat and free of curvatures. This give us plenty of

opportunity to get some hands on training. Most of these parts are non-critical

parts - that's good, because I am not sure I know what I am doing yet.

In

this Chapter, we are going to build various cross members of the aircraft. They

are the Instrument Panel, Seat Back, Landing Gear Bulkheads, Firewall and a

couple front panels namely F22 and F28. Since this is the first chapter,

all the parts are flat and free of curvatures. This give us plenty of

opportunity to get some hands on training. Most of these parts are non-critical

parts - that's good, because I am not sure I know what I am doing yet.  I

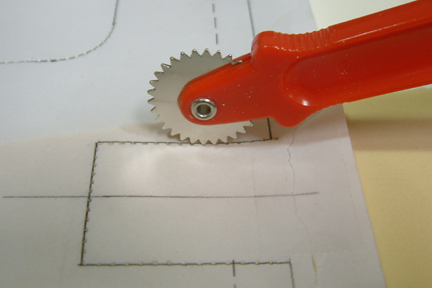

transferred the drawings onto the foam using a tracing wheel they use for sewing

(I learned this from the Cozy forum & various web sites).

I

transferred the drawings onto the foam using a tracing wheel they use for sewing

(I learned this from the Cozy forum & various web sites).

I

set the depth of cut by placing a thin

paper between the tabletop and the end of the router bit as shown. Once set, I

routed along the traced lines. When completed, only a paper-thin foam is left

connecting the bulkhead cutouts and the residual foam. Break off the bulkheads

pieces as needed. Just a slight brush off with 100 grit sandpaper will result in

smooth edges for the bulkheads.

I

set the depth of cut by placing a thin

paper between the tabletop and the end of the router bit as shown. Once set, I

routed along the traced lines. When completed, only a paper-thin foam is left

connecting the bulkhead cutouts and the residual foam. Break off the bulkheads

pieces as needed. Just a slight brush off with 100 grit sandpaper will result in

smooth edges for the bulkheads.

Due

to the slight thickness of the foam and somewhat aggressive squeezing of the BID

layers for the hard points, they ended up too thin. With some careful measuring

and estimating, I ended up with 27 layers of BID cloth instead of the 22 layers

per plan. I did get a nice flush between the hard points and the foam. You can

see the peel ply that was partially trimmed and pulled back as well as the

plastic peel ply.

Due

to the slight thickness of the foam and somewhat aggressive squeezing of the BID

layers for the hard points, they ended up too thin. With some careful measuring

and estimating, I ended up with 27 layers of BID cloth instead of the 22 layers

per plan. I did get a nice flush between the hard points and the foam. You can

see the peel ply that was partially trimmed and pulled back as well as the

plastic peel ply. I

traced out the drawings for the firewall as the other bulkheads and cut out both

the temporary and permanent ones per plan. Once made, I clamped the firewalls

together and performed the edge sanding and hole drilling together. This

way, hardware positions on the temporary and permanent firewalls will be the

same.

I

traced out the drawings for the firewall as the other bulkheads and cut out both

the temporary and permanent ones per plan. Once made, I clamped the firewalls

together and performed the edge sanding and hole drilling together. This

way, hardware positions on the temporary and permanent firewalls will be the

same. You're

probably wondering what in the world are those round inserts – instead of the

1” square inserts per plan. Based on the Wayne Hicks’ and others web site, it was

suggested that a larger insert (~1.25" sides square) might be worthwhile. Therefore, instead of the

1”x1” square inserts, I had 1.75” diameter (diagonal length of a

1.25" square) aluminum discs made in their place. Besides, it was easier to cut a round hole in the firewall (using a hole

saw) for a nice clean fit.

You're

probably wondering what in the world are those round inserts – instead of the

1” square inserts per plan. Based on the Wayne Hicks’ and others web site, it was

suggested that a larger insert (~1.25" sides square) might be worthwhile. Therefore, instead of the

1”x1” square inserts, I had 1.75” diameter (diagonal length of a

1.25" square) aluminum discs made in their place. Besides, it was easier to cut a round hole in the firewall (using a hole

saw) for a nice clean fit.