Chapter

13 - Section 11

Nose

Door

Reinforcing

the Glass Strut

Fabricating

NG-30

Installing

Worm Drive Assembly

Box

Assembly

Nose

Floor & Sides

Rudder

Pedals Master

Brake Cylinders

Completing

Nose Gear

Pitot

& Static System

Closing

the Top Nose

Door

|

I

delayed working on this section until it I reached Chapter 18 (canopy) because I

wanted to shape the nose cover, the canard cover and canopy deck all at the same

time such that I get a smooth profile from nose tip to canopy. Shaping of the above

covers is detailed in chapter 18 section 11. Once shaped, I return back to this

section to document the nose cover build. I

delayed working on this section until it I reached Chapter 18 (canopy) because I

wanted to shape the nose cover, the canard cover and canopy deck all at the same

time such that I get a smooth profile from nose tip to canopy. Shaping of the above

covers is detailed in chapter 18 section 11. Once shaped, I return back to this

section to document the nose cover build.

|

Hinge

or No-Hinge

The

first decision I have to make regarding the nose door was its attachment method.

Many builders used the hinge method and some uses the plan (screw / flap

method). I

felt there are pros and cons in both methods.

As

for the hinge method, the plane will look cleaner with no screws and it will

provide a slight level of security from break-ins. I talked to several senior builders

and even received hinge pattern from Jon Dembs - Thanks Jon. However, I was

concerned about getting a nice fit because the shape of the 'J-hook' and its

mounting method has a lot to

do with it. I have heard multiple builders having difficulty in keeping their

seams tight and even in all sides. I also do not like the door hanging in the

way while I try to work inside the nose area. Most importantly, I am not sure

just the hinge and a locking mechanism (at the top side) will provide a good

seal (water and cold air) for the nose door.

The

screw method would be an easier installation and I think I'll have a much better

chance of getting the door nice and flush to the nose cover - which is important

to the appearance of the plane. In addition, I should be able to get a tight

seal from any leak as well. One of the argument regarding security is that

people will break in no matter what. But with the screw method, at least they

won't rip you door open to get at you GPS antenna - its a tough call as always. After

several days of pondering till I got over my mental indigestion ... I

finally decided to go the screw methods... hope I won't

regret my decision.

... I

finally decided to go the screw methods... hope I won't

regret my decision.

I

learned (from earlier Chapters) that deviating from plans methods always takes

longer. On the other hand, I just wasn't comfortable with the plan's method on holding down the nose door

with 2 screws and the canard cover lip. In addition, I am not certain I have the

necessary skill to carve a depression on the foam such that the nose door can sit

perfectly flush with the nose cover throughout (per plan). I decided to employ one of the techniques I

used in Chapter 13 section 5 - my removable landing light shield. Here's what I did...

| Making

the Nose Cover |

|

This

step pretty much follows the plans method. I first made a paper template of the

nose door - just to give me an idea how big the door is and how well it fits. I

did not use the door dimension per plan - I made it bigger instead. I projected

the sides of my nose cover door from the edges of the nose door

(at the tip of the nose). Then I drawn the outline

of the door on the nose cover foam. I cover the foam with

packing tape and lay up 3 plies of BID over the area. Peel plied and allowed to cure

overnight. Once cured, I carefully marked the location of the 'door' to the

center line of the fuselage as well as other markings to make sure I can put the

door back at the exact location later - this is important! Then I

removed the door and set aside for later use. This

step pretty much follows the plans method. I first made a paper template of the

nose door - just to give me an idea how big the door is and how well it fits. I

did not use the door dimension per plan - I made it bigger instead. I projected

the sides of my nose cover door from the edges of the nose door

(at the tip of the nose). Then I drawn the outline

of the door on the nose cover foam. I cover the foam with

packing tape and lay up 3 plies of BID over the area. Peel plied and allowed to cure

overnight. Once cured, I carefully marked the location of the 'door' to the

center line of the fuselage as well as other markings to make sure I can put the

door back at the exact location later - this is important! Then I

removed the door and set aside for later use.

|

| Glassing

the Nose |

|

This

is where I deviate from plan...instead

of carving a step/trench on the nose foam to accommodate the door, I glassed

(2 ply BID) and peel plied the entire nose cover as is. Once cured, I removed

the peel ply and re-traced an outline of the nose door on the top of the glass again (using the paper template). With my FEIN tool, long box cutter blades and circle

cutter, I cut

out the the door opening and push it out (as shown left). This

is where I deviate from plan...instead

of carving a step/trench on the nose foam to accommodate the door, I glassed

(2 ply BID) and peel plied the entire nose cover as is. Once cured, I removed

the peel ply and re-traced an outline of the nose door on the top of the glass again (using the paper template). With my FEIN tool, long box cutter blades and circle

cutter, I cut

out the the door opening and push it out (as shown left).

It

is important to note that the nose door corners are rounded. Therefore, it was difficult to make a perfectly smooth cut around the corners and at the

same time with a very narrow cut groove. If you look close at many Cozy nose

doors in the flight line, most of them have a wide seam and uneven widths... Since this is

the most 'looked' area, I wanted to do my best to impress ... ...

Even

with utmost care, the nose door I cut out has uneven corners and uneven seams -

but wait, I can do something about it! The cut out nose door & foam is

discarded. I

used my sanding stick, block, dowel etc. and clean off its edges of the cut out

hole - until I got a

nice, evenly shaped, clean opening.

|

|

Now,

I laid the nose door (I made earlier) over the nice door opening - making sure it sat

exactly on the alignment marks. I tape the door down to the nose temporarily.

Using a fine tip Sharpie, I traced out the door opening onto the underside of

the nose door. Now,

I laid the nose door (I made earlier) over the nice door opening - making sure it sat

exactly on the alignment marks. I tape the door down to the nose temporarily.

Using a fine tip Sharpie, I traced out the door opening onto the underside of

the nose door.

|

|

Then

I trim the nose door to the Sharpie outline - which will fit EXACTLY to the nose

door opening, with perfectly rounded corners and no seam! The 2 duct tape

'handles' allows me to pick up the nose door during my fitting process because

the door fits the opening nicely, there is no lip or edge for me to grab on

to. Then

I trim the nose door to the Sharpie outline - which will fit EXACTLY to the nose

door opening, with perfectly rounded corners and no seam! The 2 duct tape

'handles' allows me to pick up the nose door during my fitting process because

the door fits the opening nicely, there is no lip or edge for me to grab on

to.

I

bondoed stir sticks to the door to keep it flush to the nose cover for the next step.

|

Cutting

Out the Nose Cover Block

Before

cutting the nose cover block, I placed 3 markers on each side of the nose block

such that I can put them back on the exact location later on. Then I used my FEIN tool and cut along the sides. The

nose cover popped off easily since I was holding it down with only 3 dabs of 5

minute epoxy on each side.

| Stiffening

the Nose Door |

|

Per

plan, my nose door was made out of 3 BID layers and is a bit flimsy. I

decided to beef it up a bit such that it can accommodate the counter sink hold

down screws. With the door bondoed flush to the cover (above) and the nose cover

cut away from the fuselage, I can flip the cover over. Per

plan, my nose door was made out of 3 BID layers and is a bit flimsy. I

decided to beef it up a bit such that it can accommodate the counter sink hold

down screws. With the door bondoed flush to the cover (above) and the nose cover

cut away from the fuselage, I can flip the cover over.

I

removed a .5" strip of foam (from the cover) around the door cover and sand it

down to the glass. I laid packing tape all around this newly exposed glass (around the

door). I made a 6 BID frame for the door, approximately 2"

wide, and glassed it in carefully, then peel plied.

After

cure, I removed all the bondoed sticks and pop the door back out - just to make sure I did not accidentally glass

the door to the nose cover ...This time I learned, I

heated up the bondo with a hair dryer before removing them - much easier. ...This time I learned, I

heated up the bondo with a hair dryer before removing them - much easier.

|

| Glassing

In The Support Flange |

|

I

wrapped the edges of the door with packing tape and fit it back in place (with

slight force fit). I kept

the door flush with the nose surface using stir stick and hot glue this time

(instead of bondo). It worked

just as well (as bondo), except its easier to apply and cures quicker...and

probably much easier to remove later on. I

wrapped the edges of the door with packing tape and fit it back in place (with

slight force fit). I kept

the door flush with the nose surface using stir stick and hot glue this time

(instead of bondo). It worked

just as well (as bondo), except its easier to apply and cures quicker...and

probably much easier to remove later on.

Prior

to glassing, I added a flox fillet along the added thickness of the door. I

made a 3 BID frame (~1.75" wide) and glassed it from the exposed edge of

the cover (around the frame) and over the door frame - creating a support

flange. While wet, I added strips of BID (7 layers) on top of the initial 3

BID frame - totaling 10 layers. The reason for so many layers such that I can

make a groove to bury a o-ring cord stock seal later on.

|

|

Here's a picture of the support flange. I has yet to be trimmed

it to the correct width. The door fits well - perfectly flush and no gap in all

sides . .

|

| Carving

The Cover Underside |

|

The

joining location of my nose cover to the side of the fuselage is a bit different

than shown in the plans (Fig. 65). Therefore, I just have to be a bit creative

in interpreting what is required in carving the bottom sides of the cover.

Here's what I ended up with...If you look close, I have already trimmed the

support flange to .75" width. I have also microed the foam ready for

glassing. One location I wasn't sure about is at the opening between F0 and F5.

It needs to be protected because it will be exposed to weather elements - yet I

have no way of sealing it unless I take the nose wheel strut off...what a pain.

I decided to glass over the whole thing first and remember to seal it off when

opportunity arises. The

joining location of my nose cover to the side of the fuselage is a bit different

than shown in the plans (Fig. 65). Therefore, I just have to be a bit creative

in interpreting what is required in carving the bottom sides of the cover.

Here's what I ended up with...If you look close, I have already trimmed the

support flange to .75" width. I have also microed the foam ready for

glassing. One location I wasn't sure about is at the opening between F0 and F5.

It needs to be protected because it will be exposed to weather elements - yet I

have no way of sealing it unless I take the nose wheel strut off...what a pain.

I decided to glass over the whole thing first and remember to seal it off when

opportunity arises.

|

| Glassing

Under Side of Cover & Nut Plates |

|

Here's

a picture showing the underside of the cover after it had been glassed, peel plied and trimmed - 1

BID per plan. I also added 4 mounting screws that matches the ones used for the

forward nose cover. They are MS24694-S11 (8-32) stainless machine screws and

matching nut plates. Here's

a picture showing the underside of the cover after it had been glassed, peel plied and trimmed - 1

BID per plan. I also added 4 mounting screws that matches the ones used for the

forward nose cover. They are MS24694-S11 (8-32) stainless machine screws and

matching nut plates.

|

Tool

Compartment (not in Plans)

While

I had the nose cover cut out, I took the opportunity to install a tool

compartment (i.e. a set of

bulkhead) at the front of the nose as most builders. I set the bulkhead location

about 9" from F0 because it will give me a diagonal dimension of exactly 1

foot. Since I have already made room at the nose compartment for ballast, this

added compartment shall be used for storing necessary tools (see 2 pictures

below).

Painting

Inside the Nose

There

are many discussions in the archives regarding interior paints. Some suggested

Stone Flack (spray cans) and others Zalotone (HPLV spray paint) . I just wasn't

ready for the whole interior finishing and painting mode, I decided to go with

the Stone Flack spray paint even though most suggested that Stone Fleck will not

last as long as Zolatone. Matter of fact, some builders suggested no paint at

all because no one can see under the nose cover anyway - save some weight. I

know I won't be happy with bare glass and this is the best time to get it

covered up...

|

I

first mask off all necessary areas and did a bit of pre-filling (dry micro). Got

a taste of what Chapter 25 (finishing) is all about. I think its gonna be one

tough chapter coming up I

first mask off all necessary areas and did a bit of pre-filling (dry micro). Got

a taste of what Chapter 25 (finishing) is all about. I think its gonna be one

tough chapter coming up ... Note

that small white spot on the floor? Feels like eternity to get a nice

contour. ... Note

that small white spot on the floor? Feels like eternity to get a nice

contour.

|

|

Shopping

of Stone Flack was a bit more effort than expected. I preferred lighter cover

for my interior and I eventually found them at the local fabric store (JoAnn's)

instead of Home Deport and Lowes. I used white primer (Plastic Kote), Soapstone

(Plastic Kote - Stone Flack) and Clear Coat (Krylone - UV resistance & non-yellowing). I

decided to use

a light coat of Stone Flack (just enough to camouflage the glass weaves) and the

white primer help to minimize Stone Flack coverage. Once completed, I sprayed 3

layers of Clear Coat. It turned out quite nice Shopping

of Stone Flack was a bit more effort than expected. I preferred lighter cover

for my interior and I eventually found them at the local fabric store (JoAnn's)

instead of Home Deport and Lowes. I used white primer (Plastic Kote), Soapstone

(Plastic Kote - Stone Flack) and Clear Coat (Krylone - UV resistance & non-yellowing). I

decided to use

a light coat of Stone Flack (just enough to camouflage the glass weaves) and the

white primer help to minimize Stone Flack coverage. Once completed, I sprayed 3

layers of Clear Coat. It turned out quite nice ...though

the picture is a bit small to see. ...though

the picture is a bit small to see.

|

| Glassing

the Nose Top |

|

Once

the interior paint cured, I place the nose cover back in place per my alignment

marks (I drawn 6 vertical line along the sides before I cutting the nose top

off). Then I mount the canard back in place and bolted it down. The reason for

mounting the canard is to make sure the nose will be glassed in position in

concert with the canard alignment pins and bolts. Once

the interior paint cured, I place the nose cover back in place per my alignment

marks (I drawn 6 vertical line along the sides before I cutting the nose top

off). Then I mount the canard back in place and bolted it down. The reason for

mounting the canard is to make sure the nose will be glassed in position in

concert with the canard alignment pins and bolts.

I

dug the trenches way too deep and I know I am going to have a lot to fill down

the road.

|

Torsional

Brace (Removable) - Not In Plans

This

is another one of those waterfall effects from deviating (from Plans) prior .

Instead of using the plans method for the rudder pedals, I change to the

Velocity design hanging type pedals. In addition, I re-design the Velocity

pedals (refer to Chapter 13 section 7) and mounted it a bit differently. Bottom

line is that I can only remove my rudder pedals by lifting it straight up.

.

Instead of using the plans method for the rudder pedals, I change to the

Velocity design hanging type pedals. In addition, I re-design the Velocity

pedals (refer to Chapter 13 section 7) and mounted it a bit differently. Bottom

line is that I can only remove my rudder pedals by lifting it straight up.

|

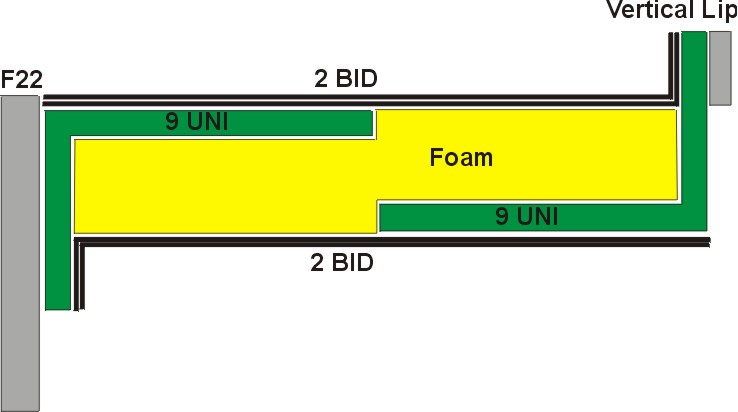

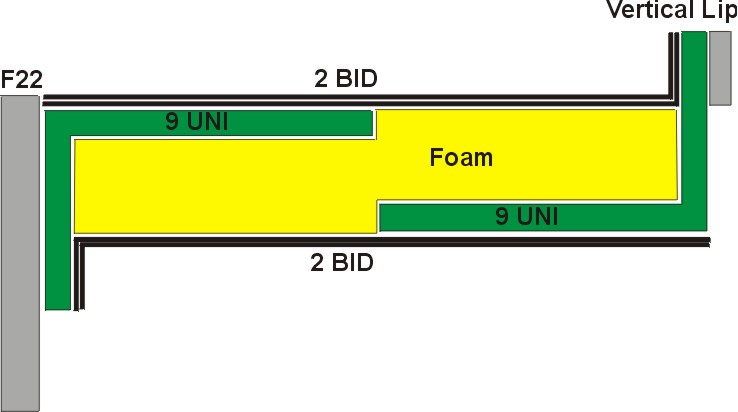

Here's

the challenge - the Plans torsional brace consists of a 3/8" foam piece with 1 ply of BID

connecting (glassed) F22 to the aft end of the nose cover. If I follow the Plans

approach, my rudder pedals will be entombed... Therefore, I need to build a removable

one - just incase. Picture (left) shows the general idea... Here's

the challenge - the Plans torsional brace consists of a 3/8" foam piece with 1 ply of BID

connecting (glassed) F22 to the aft end of the nose cover. If I follow the Plans

approach, my rudder pedals will be entombed... Therefore, I need to build a removable

one - just incase. Picture (left) shows the general idea...

|

Vertical

Lip for Mounting the Removable Brace

First

I cut a strip of high density foam about 1.5" width x 29" long and

glassed it with 2 plies of BID per side. After it cures, I glassed it

to the aft end of the nose cover with 2 BID inside and outside forming a

vertical lip (gray).

|

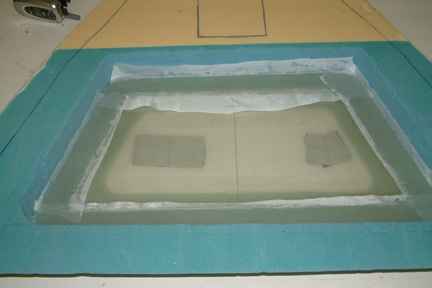

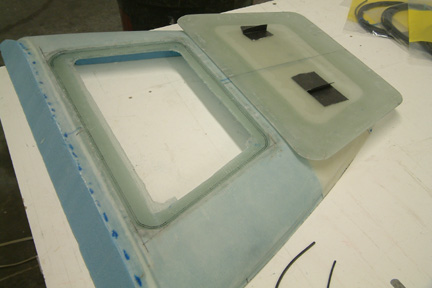

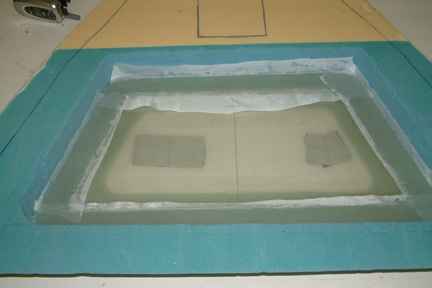

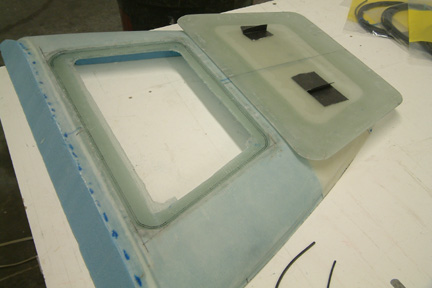

Next,

I build a set of glass angle strips (9 Ply UNI) as shown. Once cured, I cut it

in half down the center, lengthwise, forming 2 strips of glass angles (green). Next,

I build a set of glass angle strips (9 Ply UNI) as shown. Once cured, I cut it

in half down the center, lengthwise, forming 2 strips of glass angles (green).

|

|

I

measured and cut out a piece of 3/8" foam (yellow) with its width that fits snuggly

between F22 and the vertical lip. Then I sand a depression (lengthwise) on each

side of the foam to embed the glass angle strip I made (above). I

measured and cut out a piece of 3/8" foam (yellow) with its width that fits snuggly

between F22 and the vertical lip. Then I sand a depression (lengthwise) on each

side of the foam to embed the glass angle strip I made (above).

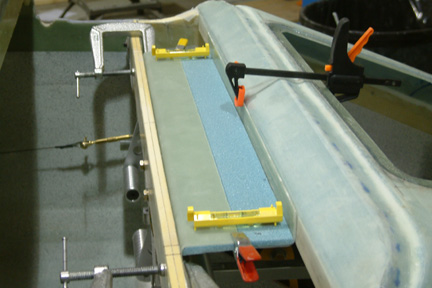

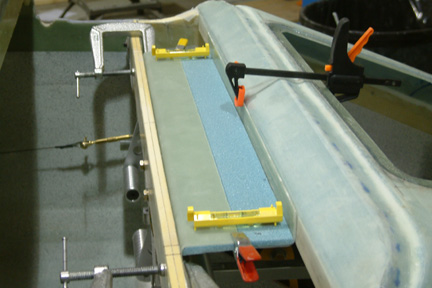

I

clamped the assembly in place (left) and laid 2 plies of BID on both top -

connecting the 2 angle strips together. Once cured, I flip the brace over and

glassed the bottom side with 2 BID - forming a strong & rigid brace that I

can bolt onto F20 and vertical lip. Note the 2 miniature (yellow) bubble levels

I used to keep the brace level during installation.

|

|

Here's

a completed brace with 4 AN-3 bolts on each lip. I may install a set of nut

plates for it later on... Here's

a completed brace with 4 AN-3 bolts on each lip. I may install a set of nut

plates for it later on...

|

Things

To Do...

-

Seal off nose cover with BID tape from inside of F0, F5 and NG30.

-

Seal off nose door with o-ring chord stock, if necessary.

I

delayed working on this section until it I reached Chapter 18 (canopy) because I

wanted to shape the nose cover, the canard cover and canopy deck all at the same

time such that I get a smooth profile from nose tip to canopy. Shaping of the above

covers is detailed in chapter 18 section 11. Once shaped, I return back to this

section to document the nose cover build.

I

delayed working on this section until it I reached Chapter 18 (canopy) because I

wanted to shape the nose cover, the canard cover and canopy deck all at the same

time such that I get a smooth profile from nose tip to canopy. Shaping of the above

covers is detailed in chapter 18 section 11. Once shaped, I return back to this

section to document the nose cover build. This

step pretty much follows the plans method. I first made a paper template of the

nose door - just to give me an idea how big the door is and how well it fits. I

did not use the door dimension per plan - I made it bigger instead. I projected

the sides of my nose cover door from the edges of the nose door

(at the tip of the nose). Then I drawn the outline

of the door on the nose cover foam. I cover the foam with

packing tape and lay up 3 plies of BID over the area. Peel plied and allowed to cure

overnight. Once cured, I carefully marked the location of the 'door' to the

center line of the fuselage as well as other markings to make sure I can put the

door back at the exact location later - this is important! Then I

removed the door and set aside for later use.

This

step pretty much follows the plans method. I first made a paper template of the

nose door - just to give me an idea how big the door is and how well it fits. I

did not use the door dimension per plan - I made it bigger instead. I projected

the sides of my nose cover door from the edges of the nose door

(at the tip of the nose). Then I drawn the outline

of the door on the nose cover foam. I cover the foam with

packing tape and lay up 3 plies of BID over the area. Peel plied and allowed to cure

overnight. Once cured, I carefully marked the location of the 'door' to the

center line of the fuselage as well as other markings to make sure I can put the

door back at the exact location later - this is important! Then I

removed the door and set aside for later use.  This

is where I deviate from plan...instead

of carving a step/trench on the nose foam to accommodate the door, I glassed

(2 ply BID) and peel plied the entire nose cover as is. Once cured, I removed

the peel ply and re-traced an outline of the nose door on the top of the glass again (using the paper template). With my FEIN tool, long box cutter blades and circle

cutter, I cut

out the the door opening and push it out (as shown left).

This

is where I deviate from plan...instead

of carving a step/trench on the nose foam to accommodate the door, I glassed

(2 ply BID) and peel plied the entire nose cover as is. Once cured, I removed

the peel ply and re-traced an outline of the nose door on the top of the glass again (using the paper template). With my FEIN tool, long box cutter blades and circle

cutter, I cut

out the the door opening and push it out (as shown left).  Now,

I laid the nose door (I made earlier) over the nice door opening - making sure it sat

exactly on the alignment marks. I tape the door down to the nose temporarily.

Using a fine tip Sharpie, I traced out the door opening onto the underside of

the nose door.

Now,

I laid the nose door (I made earlier) over the nice door opening - making sure it sat

exactly on the alignment marks. I tape the door down to the nose temporarily.

Using a fine tip Sharpie, I traced out the door opening onto the underside of

the nose door.  Then

I trim the nose door to the Sharpie outline - which will fit EXACTLY to the nose

door opening, with perfectly rounded corners and no seam! The 2 duct tape

'handles' allows me to pick up the nose door during my fitting process because

the door fits the opening nicely, there is no lip or edge for me to grab on

to.

Then

I trim the nose door to the Sharpie outline - which will fit EXACTLY to the nose

door opening, with perfectly rounded corners and no seam! The 2 duct tape

'handles' allows me to pick up the nose door during my fitting process because

the door fits the opening nicely, there is no lip or edge for me to grab on

to. Per

plan, my nose door was made out of 3 BID layers and is a bit flimsy. I

decided to beef it up a bit such that it can accommodate the counter sink hold

down screws. With the door bondoed flush to the cover (above) and the nose cover

cut away from the fuselage, I can flip the cover over.

Per

plan, my nose door was made out of 3 BID layers and is a bit flimsy. I

decided to beef it up a bit such that it can accommodate the counter sink hold

down screws. With the door bondoed flush to the cover (above) and the nose cover

cut away from the fuselage, I can flip the cover over. I

wrapped the edges of the door with packing tape and fit it back in place (with

slight force fit). I kept

the door flush with the nose surface using stir stick and hot glue this time

(instead of bondo). It worked

just as well (as bondo), except its easier to apply and cures quicker...and

probably much easier to remove later on.

I

wrapped the edges of the door with packing tape and fit it back in place (with

slight force fit). I kept

the door flush with the nose surface using stir stick and hot glue this time

(instead of bondo). It worked

just as well (as bondo), except its easier to apply and cures quicker...and

probably much easier to remove later on.

The

joining location of my nose cover to the side of the fuselage is a bit different

than shown in the plans (Fig. 65). Therefore, I just have to be a bit creative

in interpreting what is required in carving the bottom sides of the cover.

Here's what I ended up with...If you look close, I have already trimmed the

support flange to .75" width. I have also microed the foam ready for

glassing. One location I wasn't sure about is at the opening between F0 and F5.

It needs to be protected because it will be exposed to weather elements - yet I

have no way of sealing it unless I take the nose wheel strut off...what a pain.

I decided to glass over the whole thing first and remember to seal it off when

opportunity arises.

The

joining location of my nose cover to the side of the fuselage is a bit different

than shown in the plans (Fig. 65). Therefore, I just have to be a bit creative

in interpreting what is required in carving the bottom sides of the cover.

Here's what I ended up with...If you look close, I have already trimmed the

support flange to .75" width. I have also microed the foam ready for

glassing. One location I wasn't sure about is at the opening between F0 and F5.

It needs to be protected because it will be exposed to weather elements - yet I

have no way of sealing it unless I take the nose wheel strut off...what a pain.

I decided to glass over the whole thing first and remember to seal it off when

opportunity arises. Here's

a picture showing the underside of the cover after it had been glassed, peel plied and trimmed - 1

BID per plan. I also added 4 mounting screws that matches the ones used for the

forward nose cover. They are MS24694-S11 (8-32) stainless machine screws and

matching nut plates.

Here's

a picture showing the underside of the cover after it had been glassed, peel plied and trimmed - 1

BID per plan. I also added 4 mounting screws that matches the ones used for the

forward nose cover. They are MS24694-S11 (8-32) stainless machine screws and

matching nut plates.  I

first mask off all necessary areas and did a bit of pre-filling (dry micro). Got

a taste of what Chapter 25 (finishing) is all about. I think its gonna be one

tough chapter coming up

I

first mask off all necessary areas and did a bit of pre-filling (dry micro). Got

a taste of what Chapter 25 (finishing) is all about. I think its gonna be one

tough chapter coming up Shopping

of Stone Flack was a bit more effort than expected. I preferred lighter cover

for my interior and I eventually found them at the local fabric store (JoAnn's)

instead of Home Deport and Lowes. I used white primer (Plastic Kote), Soapstone

(Plastic Kote - Stone Flack) and Clear Coat (Krylone - UV resistance & non-yellowing). I

decided to use

a light coat of Stone Flack (just enough to camouflage the glass weaves) and the

white primer help to minimize Stone Flack coverage. Once completed, I sprayed 3

layers of Clear Coat. It turned out quite nice

Shopping

of Stone Flack was a bit more effort than expected. I preferred lighter cover

for my interior and I eventually found them at the local fabric store (JoAnn's)

instead of Home Deport and Lowes. I used white primer (Plastic Kote), Soapstone

(Plastic Kote - Stone Flack) and Clear Coat (Krylone - UV resistance & non-yellowing). I

decided to use

a light coat of Stone Flack (just enough to camouflage the glass weaves) and the

white primer help to minimize Stone Flack coverage. Once completed, I sprayed 3

layers of Clear Coat. It turned out quite nice Once

the interior paint cured, I place the nose cover back in place per my alignment

marks (I drawn 6 vertical line along the sides before I cutting the nose top

off). Then I mount the canard back in place and bolted it down. The reason for

mounting the canard is to make sure the nose will be glassed in position in

concert with the canard alignment pins and bolts.

Once

the interior paint cured, I place the nose cover back in place per my alignment

marks (I drawn 6 vertical line along the sides before I cutting the nose top

off). Then I mount the canard back in place and bolted it down. The reason for

mounting the canard is to make sure the nose will be glassed in position in

concert with the canard alignment pins and bolts. Here's

the challenge - the Plans torsional brace consists of a 3/8" foam piece with 1 ply of BID

connecting (glassed) F22 to the aft end of the nose cover. If I follow the Plans

approach, my rudder pedals will be entombed... Therefore, I need to build a removable

one - just incase. Picture (left) shows the general idea...

Here's

the challenge - the Plans torsional brace consists of a 3/8" foam piece with 1 ply of BID

connecting (glassed) F22 to the aft end of the nose cover. If I follow the Plans

approach, my rudder pedals will be entombed... Therefore, I need to build a removable

one - just incase. Picture (left) shows the general idea... Next,

I build a set of glass angle strips (9 Ply UNI) as shown. Once cured, I cut it

in half down the center, lengthwise, forming 2 strips of glass angles (green).

Next,

I build a set of glass angle strips (9 Ply UNI) as shown. Once cured, I cut it

in half down the center, lengthwise, forming 2 strips of glass angles (green). I

measured and cut out a piece of 3/8" foam (yellow) with its width that fits snuggly

between F22 and the vertical lip. Then I sand a depression (lengthwise) on each

side of the foam to embed the glass angle strip I made (above).

I

measured and cut out a piece of 3/8" foam (yellow) with its width that fits snuggly

between F22 and the vertical lip. Then I sand a depression (lengthwise) on each

side of the foam to embed the glass angle strip I made (above). Here's

a completed brace with 4 AN-3 bolts on each lip. I may install a set of nut

plates for it later on...

Here's

a completed brace with 4 AN-3 bolts on each lip. I may install a set of nut

plates for it later on...