In

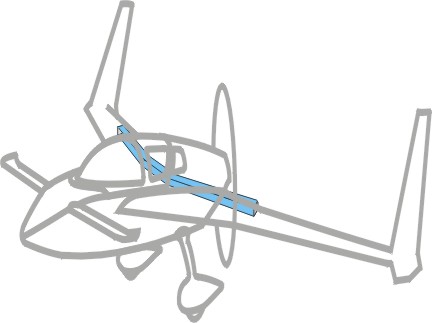

this chapter, we will build the center section spar which joins the wing to the

fuselage. The center section spar is the heart of the wing structure, so

accuracy is important. Note that the top of the spar is flat: that it

sweeps aft and that the bottom has positive dihedral in order for fuel to run

inboard while in level flight.

In

this chapter, we will build the center section spar which joins the wing to the

fuselage. The center section spar is the heart of the wing structure, so

accuracy is important. Note that the top of the spar is flat: that it

sweeps aft and that the bottom has positive dihedral in order for fuel to run

inboard while in level flight.

[Hindsight]

This chapter is not as difficult as some of the previous ones. However, some sessions

take a LOT of effort and time to complete. Stopping mid-stream is not

recommended. Therefore, one of the most important preparations for this chapter

is to smooch up to your better half or someone who can give you a hand down the

road![]() , not once, but at least

3 times...unless, you plan to work on these sessions by yourself, non-stop for a

minimum 12 hours!

, not once, but at least

3 times...unless, you plan to work on these sessions by yourself, non-stop for a

minimum 12 hours!

The

first step of this chapter is to make a particle board jig which will be used

to support the center section spar. The first thing I did was to set up my work

table so that it can accommodate this long (12') fixture. I prepped the surface

so that it is nice and flat and re-leveled in all directions to 0.0 degrees.

With the help of my laser, I drew a straight reference line along the full

length of the table.

The

first step of this chapter is to make a particle board jig which will be used

to support the center section spar. The first thing I did was to set up my work

table so that it can accommodate this long (12') fixture. I prepped the surface

so that it is nice and flat and re-leveled in all directions to 0.0 degrees.

With the help of my laser, I drew a straight reference line along the full

length of the table. I

wasn't quite sure how part E was suppose to look per Chapter 14, Page 6. I decided

to make 2 support legs instead of 1 for better stability. Based on the slope of

part C relative to A, the angle equates to 8 1/2 degrees. I just trimmed the top

edge of part E to 8 1/2 degrees and they fit perfectly.

I

wasn't quite sure how part E was suppose to look per Chapter 14, Page 6. I decided

to make 2 support legs instead of 1 for better stability. Based on the slope of

part C relative to A, the angle equates to 8 1/2 degrees. I just trimmed the top

edge of part E to 8 1/2 degrees and they fit perfectly. To

ensure the resultant center section spar is straight and level, I confirmed the

leveling of the jig with my digital level. Note the Bondo used for holding the

jig legs together. The boards, butting against part D are to make sure it stays

straight and level throughout the assembly process.

To

ensure the resultant center section spar is straight and level, I confirmed the

leveling of the jig with my digital level. Note the Bondo used for holding the

jig legs together. The boards, butting against part D are to make sure it stays

straight and level throughout the assembly process.