Marking Hinge Pad Locations

I

first marked the 2 - 1.6" flat surfaces along the longerons. Then I joined

the dots with a flexible aluminum strip - that was straight forward.

I

first marked the 2 - 1.6" flat surfaces along the longerons. Then I joined

the dots with a flexible aluminum strip - that was straight forward.

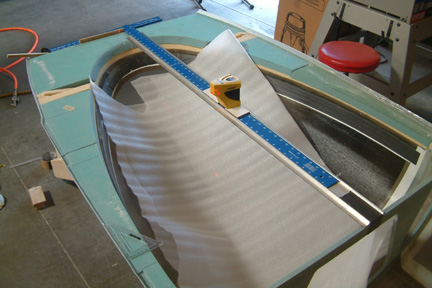

The next step was to mark the locations of the hinge pads along both sides of the longerons per Fig. 51. I set up my straight edge, T-ruler and cross-hair laser for the task (left). I made sure my T-ruler / straight edge was lined up along the center of the canopy / TB. With the cross-hair laser, I was able to determine the exact locations for the hinge and reinforcement pads along the canopy sides.

While I was fussing over the position of the straight edge, my T-ruler slipped over its side and BAM...dropped right on top of the canopy ~!@#$%^&*...~!@#$%^&*! Fortunately I had 3 layers of Spraylat on it prior. A double layer of packing material for added protection is warranted!!!

After I marked the hinge pad locations, I dug out all the foam down to the glass - creating a cavity for the subsequent step.

To

determine the foam shaping direction, I cut up a 3/4" wide strip of wood with a

line drawn along the center. I made sure the base of the strip was exactly 90o

to its center line. By butting the base of the strip against the inside

perimeter of the canopy, I basically projected a 90o line from the

tangent of the curved surface. With a cross laser, I projected this vertical line

onto the foam, thus providing me a foam shaping direction. I repeated this

process along the entire inner perimeter of the canopy, thus plotting out the

entire shaping scheme.

To

determine the foam shaping direction, I cut up a 3/4" wide strip of wood with a

line drawn along the center. I made sure the base of the strip was exactly 90o

to its center line. By butting the base of the strip against the inside

perimeter of the canopy, I basically projected a 90o line from the

tangent of the curved surface. With a cross laser, I projected this vertical line

onto the foam, thus providing me a foam shaping direction. I repeated this

process along the entire inner perimeter of the canopy, thus plotting out the

entire shaping scheme. Then

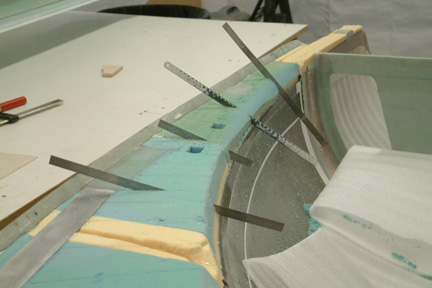

I took several straight edges and 'dug' into the foam (along the shaping

directions) with one end of the straight edge sitting on top of the canopy edge,

and the other against the foam edge per Fig. 51. The straight edges show how

much foam I need to remove at each location - looks like it's quite a bit...

Then

I took several straight edges and 'dug' into the foam (along the shaping

directions) with one end of the straight edge sitting on top of the canopy edge,

and the other against the foam edge per Fig. 51. The straight edges show how

much foam I need to remove at each location - looks like it's quite a bit... I

was a bit careful not to remove too much foam using a sanding belt. I ended up

getting a convex shape foam surface. If you look closely, you can see the

straight edge marks. Though it looked reasonably nice, it still had too much

foam left.

I

was a bit careful not to remove too much foam using a sanding belt. I ended up

getting a convex shape foam surface. If you look closely, you can see the

straight edge marks. Though it looked reasonably nice, it still had too much

foam left.  I

decided to take a more aggressive approach by using a hacksaw blade to scrape

most of the foam off. I then followed up with a foam block and 220 grit sand paper.

A lot of foam dust - but its more like it

I

decided to take a more aggressive approach by using a hacksaw blade to scrape

most of the foam off. I then followed up with a foam block and 220 grit sand paper.

A lot of foam dust - but its more like it