Chapter

18 - Section 19

Installing

Canopy Latches

There

are plenty of horror stories and discussions on the Cozy forum that relate to

the design and safety factors on our canopy latch - certainly enough to bring my

attention up front and center. That's one of the many reasons why I appreciate

the members of this forum. Their dedication to safety is

unprecedented!

Before

I get to the lock design, I need to get some latches made first. The only hardware I

was able to buy from Aircraft Spruce on this section were the C2-L and the C4A. I

decided to use 2 C4As (one on each end) such that I do not have to make a C3. I

first made the C8 brackets because they were very similar to the ones we made

for our seat belts.

|

Per

plan, I installed the three AN3-13A pivot bolts along the longeron for the C2-L.

Instead of the C1-L (the long handle), I replaced it with the third C2-L

instead. The reason for the change is because I have seen some much better

not-to-plan locking mechanisms (by other Cozy builders) and I decided to

follow... more on that later. To make sure all the hooks are synchronized, I used

a dial level, placed it against the edge of the hooks, while I adjusted the length of

C5 and C6. The only problem I encountered was that the C6A was rubbing against the seat

back. Most builders bend the tubing a bit to prevent it from rubbing. I will

probably do the same, but for now, I left it alone. The little friction seems to

keep the locks in place. Per

plan, I installed the three AN3-13A pivot bolts along the longeron for the C2-L.

Instead of the C1-L (the long handle), I replaced it with the third C2-L

instead. The reason for the change is because I have seen some much better

not-to-plan locking mechanisms (by other Cozy builders) and I decided to

follow... more on that later. To make sure all the hooks are synchronized, I used

a dial level, placed it against the edge of the hooks, while I adjusted the length of

C5 and C6. The only problem I encountered was that the C6A was rubbing against the seat

back. Most builders bend the tubing a bit to prevent it from rubbing. I will

probably do the same, but for now, I left it alone. The little friction seems to

keep the locks in place.

|

Canopy

Latch Mechanism

Wayne

Hicks had a nice write-up on his canopy latch design and I decided to follow his

scheme. However, the Hendericks lock he recommended has now come up in price to

a whopping $285 - a good incentive for improvisation...but first, I need

to make the inside latching mechanism work before anything else.

|

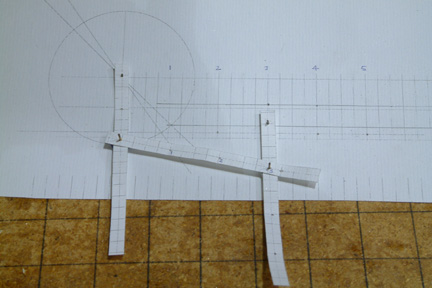

I

took precise dimensions of the latch mechanism and transferred them to a drawing

(using my Corel graphics software). I printed them out on thick report cover

paper and cut them out for paper simulation. Once I got it working correctly on

paper, I took down the final dimensions and made them out of thin aluminum.

|

|

Here's

a picture of my trial latch mechanism - I have yet to beef it up. I just

wanted to see its functionality at this time... The handle will be sitting right

in front of the control stick, providing some warning in the 'unlock' status.

|

|

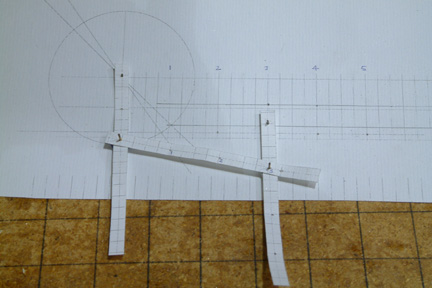

Here's

a picture showing its 'lock' position. My initial thought was to make the handle

a folding arm with a safety pin at the handle tip. Once I fold the handle in, the pin will go

through both latch arms, thus locking them in place. There is no way the latch

will open without intentionally un-folding the handle back out and disengaging

the locking pin in the process. Note the foremost latch that is a C2-L instead

of the long handle C1-L.

|

|

Once

I trial fit the latch mechanism, I replaced all washers with spacers. My

small table top lathe comes in handy for these types of turned parts. Once

I trial fit the latch mechanism, I replaced all washers with spacers. My

small table top lathe comes in handy for these types of turned parts.

|

Installing

the C8 Mounting Brackets

I

mounted the C8 latch brackets per plan. I left the IP cover off while bondoing

these brackets inside the canopy - the bondo fumes can do a number on you - I

was jolly the rest of the evening ,

just kidding... I did

not have any problems in mounting the front and middle brackets. I had to file

down the third bracket a bit to make it fit - not a big issue though. I did not

have to re-adjust the length of the connecting rods.

,

just kidding... I did

not have any problems in mounting the front and middle brackets. I had to file

down the third bracket a bit to make it fit - not a big issue though. I did not

have to re-adjust the length of the connecting rods.

Per

plan, I installed the three AN3-13A pivot bolts along the longeron for the C2-L.

Instead of the C1-L (the long handle), I replaced it with the third C2-L

instead. The reason for the change is because I have seen some much better

not-to-plan locking mechanisms (by other Cozy builders) and I decided to

follow... more on that later. To make sure all the hooks are synchronized, I used

a dial level, placed it against the edge of the hooks, while I adjusted the length of

C5 and C6. The only problem I encountered was that the C6A was rubbing against the seat

back. Most builders bend the tubing a bit to prevent it from rubbing. I will

probably do the same, but for now, I left it alone. The little friction seems to

keep the locks in place.

Per

plan, I installed the three AN3-13A pivot bolts along the longeron for the C2-L.

Instead of the C1-L (the long handle), I replaced it with the third C2-L

instead. The reason for the change is because I have seen some much better

not-to-plan locking mechanisms (by other Cozy builders) and I decided to

follow... more on that later. To make sure all the hooks are synchronized, I used

a dial level, placed it against the edge of the hooks, while I adjusted the length of

C5 and C6. The only problem I encountered was that the C6A was rubbing against the seat

back. Most builders bend the tubing a bit to prevent it from rubbing. I will

probably do the same, but for now, I left it alone. The little friction seems to

keep the locks in place.

Once

I trial fit the latch mechanism, I replaced all washers with spacers. My

small table top lathe comes in handy for these types of turned parts.

Once

I trial fit the latch mechanism, I replaced all washers with spacers. My

small table top lathe comes in handy for these types of turned parts.