Chapter

21 - Section 4

Vent,

Screen and Drain

Routing

the Vent Lines

The

plan's vent line configuration is pretty straight forward. However, as time

progresses, builders have made a few modifications to the venting configurations -

for better venting. Initially, I routed my vent lines along the edges of the

bulkheads under the T-Hats but decided against it because of the sharp bend

around the corners. It looks nice and neat while the top skin is off though... The

plan's vent line configuration is pretty straight forward. However, as time

progresses, builders have made a few modifications to the venting configurations -

for better venting. Initially, I routed my vent lines along the edges of the

bulkheads under the T-Hats but decided against it because of the sharp bend

around the corners. It looks nice and neat while the top skin is off though...

I

ended up following the plans method but added three small vertical holes through

the vent line as it exits the fuel tank (rear corner where the fuselage and

center section spar meet). I also added a couple of vertical holes at the open

end of the vent line as well. I made sure that all the vent holes were under the

T-Hats so that no flox would drip over them when I closed the top skin.

|

|

After

the vent lines exit the fuel tank, they are routed over the top of the turtleback and back down below the strake on the opposite side. My vent lines are at

the aft side of the firewall. After

the vent lines exit the fuel tank, they are routed over the top of the turtleback and back down below the strake on the opposite side. My vent lines are at

the aft side of the firewall.

|

Fuel

Return Line for Fuel Injection Engines

At

this time, I have not looked into the type of engine for my Cozy. I was told that

some fuel injection engines do not require any return lines - but they are

limited (I could be really wrong here, because I do not know much about aircraft

engines). I was recommended to put one in just in case. After much pondering, I

decided to add a fuel return to my right tank. I will certainly look for a fuel

injection engine that does not need a return line. The yellow ties are temporary.

I eventually floxed them in place. At

this time, I have not looked into the type of engine for my Cozy. I was told that

some fuel injection engines do not require any return lines - but they are

limited (I could be really wrong here, because I do not know much about aircraft

engines). I was recommended to put one in just in case. After much pondering, I

decided to add a fuel return to my right tank. I will certainly look for a fuel

injection engine that does not need a return line. The yellow ties are temporary.

I eventually floxed them in place.

|

|

[Hindsight]

I eventually ordered my engine with fuel injection that does not require a

return line. Though I can remove it at this time, I decided to plug it at the

firewall. I made a small plug with my lathe. I eventually will seal it with flox

or something. [Hindsight]

I eventually ordered my engine with fuel injection that does not require a

return line. Though I can remove it at this time, I decided to plug it at the

firewall. I made a small plug with my lathe. I eventually will seal it with flox

or something.

|

Fuel

Drain Hole

I

was rushing through the top and bottom skin and I missed the instruction for

cutting the hole for the fuel drain in the bottom skin. Fortunately I noticed it from reading

other builder's web sites. Since the location of the fuel drain is not very specific in the plan,

I figure as along as it sits over the sump blister, it should be OK.

None-the-less, I centered my fuel drain hole at 4 1/4" forward of the center

section spar face and 1 7/16" from the side of the fuselage. That puts my

fuel drain hole right at the center of the sump blister - to be built later. As I

mentioned, I missed carving a hole in the foam after I have glassed the upper

face of the bottom skin, I have to cut out the glass first, then the foam. I

have one of those circular cutter blades (shown) that I used to lance the glass

layer. Then I used a 1 1/4" hole saw and drilled out the drain hole. I dug

out the remaining glass ring with a blade. Finished the hole with a dowel and

sand paper. I

was rushing through the top and bottom skin and I missed the instruction for

cutting the hole for the fuel drain in the bottom skin. Fortunately I noticed it from reading

other builder's web sites. Since the location of the fuel drain is not very specific in the plan,

I figure as along as it sits over the sump blister, it should be OK.

None-the-less, I centered my fuel drain hole at 4 1/4" forward of the center

section spar face and 1 7/16" from the side of the fuselage. That puts my

fuel drain hole right at the center of the sump blister - to be built later. As I

mentioned, I missed carving a hole in the foam after I have glassed the upper

face of the bottom skin, I have to cut out the glass first, then the foam. I

have one of those circular cutter blades (shown) that I used to lance the glass

layer. Then I used a 1 1/4" hole saw and drilled out the drain hole. I dug

out the remaining glass ring with a blade. Finished the hole with a dowel and

sand paper.

|

Fuel

Strainer

I

bought my fuel strainer from ACE hardware store as many builders did before me.

It was a bit big but workable. The fuel strainer flange butts against the

fuselage sides and will not sit perfectly centered to the fuel drain hole. My

opportunity came when I went by an Asian supermarket (you have to live in Los

Angeles to find one of those). I found a smaller tea strainer - just a hair larger

than the fuel drain hole. You have to look at the fine print and in Chinese

that says "high quality stainless steel" I

bought my fuel strainer from ACE hardware store as many builders did before me.

It was a bit big but workable. The fuel strainer flange butts against the

fuselage sides and will not sit perfectly centered to the fuel drain hole. My

opportunity came when I went by an Asian supermarket (you have to live in Los

Angeles to find one of those). I found a smaller tea strainer - just a hair larger

than the fuel drain hole. You have to look at the fine print and in Chinese

that says "high quality stainless steel"  . .

|

|

Here's

the picture of the strainer on a scale. As shown, its a hair larger than 2"

in diameter and it will fit over the fuel drain perfectly. Here's

the picture of the strainer on a scale. As shown, its a hair larger than 2"

in diameter and it will fit over the fuel drain perfectly.

[Hindsight]

I installed this fuel strainer at the fuel inlet pipe instead of the Plan's

location. The installation is discussion in Section 4.

|

Fuel

Drain at Sump

With

the concerns (discussed above), I decided to add a second fuel drain at the

lowest point of the sump. I expect this fuel drain to catch most of the water

(in the fuel). I made up a hard point and ordered a 1/4" NPT (instead of

the 1/8") fuel drain for the purpose. The reason for the larger fuel drain

is that, in the event I need to clean out any larger debris in the sump, I will have a

least a small opening / access (~1/2") into the fuel sump. I can stick

a small vacuum tube for debris extraction.

Screen

Location

According

to the Plan, a dome shape screen is to be secured over the fuel drain hole to the sump. This

screen is to block out larger debris away from the fuel inlet lines (located in

the sump). The problem is that the location of the screen is far from the fuel

cap and its almost impossible to get to (for cleaning), once the fuel tank is

sealed. You may

be able to see the larger debris around the dome shape screen, but you may be

powerless to get to (to clean it out). I am just not too kin about this set up

though no one had any problem with it... According

to the Plan, a dome shape screen is to be secured over the fuel drain hole to the sump. This

screen is to block out larger debris away from the fuel inlet lines (located in

the sump). The problem is that the location of the screen is far from the fuel

cap and its almost impossible to get to (for cleaning), once the fuel tank is

sealed. You may

be able to see the larger debris around the dome shape screen, but you may be

powerless to get to (to clean it out). I am just not too kin about this set up

though no one had any problem with it...

Since

my second fuel drain provides a ~1/2" access hole at the sump, I decided to

move my screen right over the fuel outlet piping instead of the fuel drain hole at

the strake (Plan's location). Therefore, if there is any debris or water in the

fuel tank, they will eventually go into the sump. My fuel line will be protected

by the screen while I can drain or remove debris / water out of the fuel drain

access at the sump.

|

|

Here's

a picture of my dome shaped screen floxed and glassed in place over my fuel line. It's the same concept as the fuel line strainer that are commonly

used by other aircraft designs. Note the plane is on its upside down position. Here's

a picture of my dome shaped screen floxed and glassed in place over my fuel line. It's the same concept as the fuel line strainer that are commonly

used by other aircraft designs. Note the plane is on its upside down position.

|

Fuel

Drain at Leading Edge

The

Feather Lite leading edge does not have a 'front fence TLE' to herd any water

condensation to the fuel drain. It would be very difficult to 'catch' the water

condensation with this fuel drain. My bigger concern is that - what if the water

went down to the sump? I will never be able to get them out. After much consideration, I decided to

add a second fuel drain at the low point of the fuel sump. I followed the plans instructions for mounting

the fuel drain at the wing's leading edge.

|

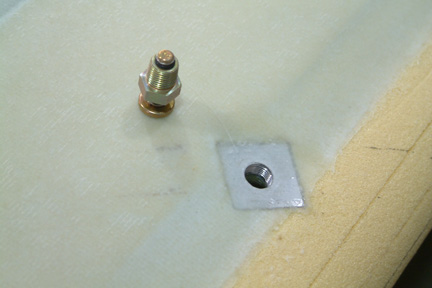

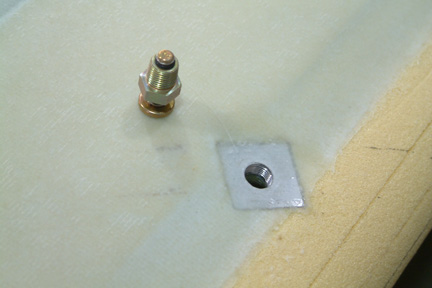

A

builder experienced a leak at this exact location. In

order to safeguard this from happening, I decided to devise some way to squeeze

the hard point against the glass during cure. I

drilled a small hole through the 1/8" NPT plug (note the hole through the

silver color plug to the left of the picture) to allow a small bolt to go

through. Picture

(left) shows the 1"x1"x1/4" hard point, the 1/8" NPT plug

(with a drilled hole), a common bolt and nut and a fuel

drain. A

builder experienced a leak at this exact location. In

order to safeguard this from happening, I decided to devise some way to squeeze

the hard point against the glass during cure. I

drilled a small hole through the 1/8" NPT plug (note the hole through the

silver color plug to the left of the picture) to allow a small bolt to go

through. Picture

(left) shows the 1"x1"x1/4" hard point, the 1/8" NPT plug

(with a drilled hole), a common bolt and nut and a fuel

drain.

|

|

Once the hard point is

buried in foam with flox, I slipped the small bolt through the 1/8" plug and hand

tightened the nut. This helped to bring the hard point tight against the

underlying glass, thus squeezing the flox nicely in between to cure. Once the hard point is

buried in foam with flox, I slipped the small bolt through the 1/8" plug and hand

tightened the nut. This helped to bring the hard point tight against the

underlying glass, thus squeezing the flox nicely in between to cure.

|

|

Here's

a picture of my fuel drain at the leading edge. Here's

a picture of my fuel drain at the leading edge.

Note

that the fuselage is upside down for glassing the bottom skin. After the glass

cured, I clear out the threaded hole.

|

Fuel

Sight Gauge

I

did not install the fuel sight gauge until I know where the bottom of the fuel

tanks are. I learned that the 'window' I made in Chapter 5 were ~1/2" too

low. I have to trim the fuel sight gauges shorter to fit them in position such

that the drain holes will be situated at the bottom of the fuel tank. I also

epoxied the metal inserts onto the sight gauges to prevent them from plugging up

(per some Cozy fliers).

|

Here's

a picture on epoxying the viewing glass onto the white back plate. Here's

a picture on epoxying the viewing glass onto the white back plate.

|

|

I

also made a 1 layer glass template around the viewing window of the sight gauge

such that I will have a more defined (cleaner) outline when it is glassed in

place. I have seen some pretty rough looking edges around the sight gauges at

some of the Cozy meets. I

also made a 1 layer glass template around the viewing window of the sight gauge

such that I will have a more defined (cleaner) outline when it is glassed in

place. I have seen some pretty rough looking edges around the sight gauges at

some of the Cozy meets.

You

can see the metal inserts as well as the BID template around the viewing window.

Since

the fuel sight gauge position is dependent on the lower drain hole relative to

the bottom of the fuel tank, I predrilled the bottom at the fuselage first. Then

I trimmed the fuel sight gauge to fit inside the fuselage cavity. The space is

tight but it worked out OK for me. Then I microed the sight gauge in place and

glassed over the entire gauge with 2 layers of BID. The LED (supplied) was also

glassed in place at the same time.

|

Fuel

Probe

The

Princeton fuel probe is a popular added feature among Cozy builders. I decided

to add a set as well. I was not able to get any return phone call from Todd

after repeated calls. I ended up buying the Princeton Advance Probe from

Aircraft Spruce. I also requested an 18" long cable at the end of the probe

with no additional cost. As many builders, I cut the probes to length - 7

3/4", leaving 1/8" spacing between the tip of the probe and the bottom

of the fuel tank.

|

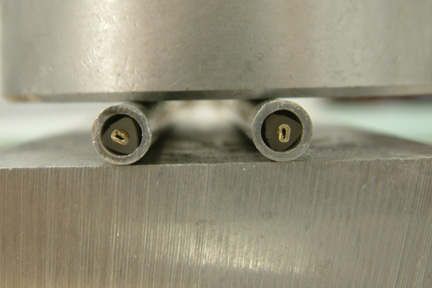

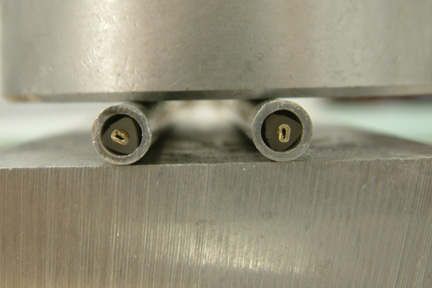

I

did not like cutting the probe with my Dremel (on my trial run) - quite a bit of

vibration and heat build up. I ended up cutting it off with my table top lathe -

resulting in a much cleaner cut with much less heat being generated. Make sure you

do not lose those 'mini' triangular spacers to keep the center probe from

touching the outside tube (housing). I learned from the Cozy forum to pinch the

inner OR the outer tube to keep the 'mini' triangular spacer from slipping out

in time. I chose the easy way by squeezing the inner tube with a pair of pointed

nose pliers. Note the inner tube ends are not round anymore. If you look close,

you can see the 'mini' triangular spacers hidden in the tube ends. I

did not like cutting the probe with my Dremel (on my trial run) - quite a bit of

vibration and heat build up. I ended up cutting it off with my table top lathe -

resulting in a much cleaner cut with much less heat being generated. Make sure you

do not lose those 'mini' triangular spacers to keep the center probe from

touching the outside tube (housing). I learned from the Cozy forum to pinch the

inner OR the outer tube to keep the 'mini' triangular spacer from slipping out

in time. I chose the easy way by squeezing the inner tube with a pair of pointed

nose pliers. Note the inner tube ends are not round anymore. If you look close,

you can see the 'mini' triangular spacers hidden in the tube ends.

|

Fuel

Probe Position

It

took me a while before deciding how and where to mount the fuel probes. I wanted

to mount the probes vertically down from the top skin and where the fuel level

is most stable. I was told it should be at FS103. The problem is that if I put

it so far forward, I may have a problem in hiding it under the fairing. I

decided to move it back a bit, actually right over the fuel drain hole and

3/8" from the side of the fuselage.

|

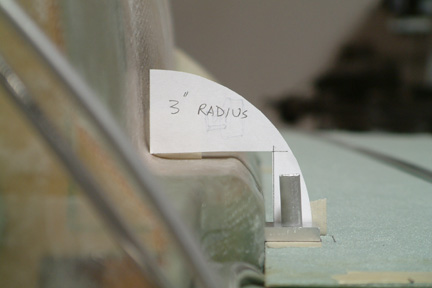

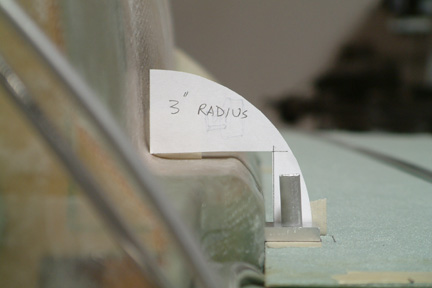

I

made a 1" square 1/4" thick aluminum hard point (with an 1/8" NPT)

for mounting the probes. To make sure I can hide the head of the probes

under the top fairings, I made a 3" and 4" paper template and held it

up against the canopy. Looks like I can hide it even with a 3" radius

fairing. I

made a 1" square 1/4" thick aluminum hard point (with an 1/8" NPT)

for mounting the probes. To make sure I can hide the head of the probes

under the top fairings, I made a 3" and 4" paper template and held it

up against the canopy. Looks like I can hide it even with a 3" radius

fairing.

|

Completing Vent Lines

I

did not return to the vent lines until I started working on the firewall aft in

Chapter 23. There were many discussion in the Cozy Forum regarding the pros and

cons of the small holes at the back of the vent lines. I decided to leave them

the way it is. In addition, I added a center block (per Buly) to relieve the

tank pressure between the two tanks as well as potential siphoning effect. I

also anchored the vent lines with multiple hose clamps as shown. I

did not return to the vent lines until I started working on the firewall aft in

Chapter 23. There were many discussion in the Cozy Forum regarding the pros and

cons of the small holes at the back of the vent lines. I decided to leave them

the way it is. In addition, I added a center block (per Buly) to relieve the

tank pressure between the two tanks as well as potential siphoning effect. I

also anchored the vent lines with multiple hose clamps as shown.

|

|

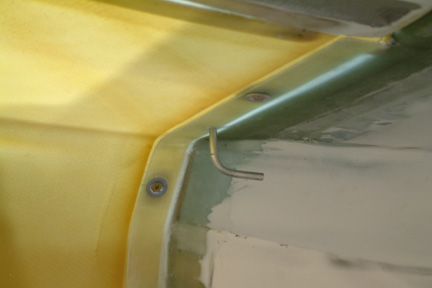

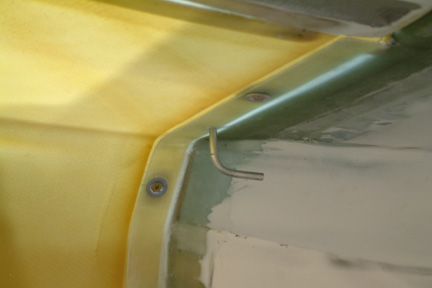

Here's

a picture showing the vent line exiting the cowling. I have to drill a 1/4" hole

through the strake lip for the vent line to exit. I also had to cut a small slot

on the cowling to accommodate the same. Here's

a picture showing the vent line exiting the cowling. I have to drill a 1/4" hole

through the strake lip for the vent line to exit. I also had to cut a small slot

on the cowling to accommodate the same.

|

|

Here's

a picture showing the vent line outside the fuselage. Supposedly, the ram air

plays a small part in keeping the fuel from spilling out of the tank when it is

under pressure. Here's

a picture showing the vent line outside the fuselage. Supposedly, the ram air

plays a small part in keeping the fuel from spilling out of the tank when it is

under pressure.

|

The

plan's vent line configuration is pretty straight forward. However, as time

progresses, builders have made a few modifications to the venting configurations -

for better venting. Initially, I routed my vent lines along the edges of the

bulkheads under the T-Hats but decided against it because of the sharp bend

around the corners. It looks nice and neat while the top skin is off though...

The

plan's vent line configuration is pretty straight forward. However, as time

progresses, builders have made a few modifications to the venting configurations -

for better venting. Initially, I routed my vent lines along the edges of the

bulkheads under the T-Hats but decided against it because of the sharp bend

around the corners. It looks nice and neat while the top skin is off though... After

the vent lines exit the fuel tank, they are routed over the top of the turtleback and back down below the strake on the opposite side. My vent lines are at

the aft side of the firewall.

After

the vent lines exit the fuel tank, they are routed over the top of the turtleback and back down below the strake on the opposite side. My vent lines are at

the aft side of the firewall.  At

this time, I have not looked into the type of engine for my Cozy. I was told that

some fuel injection engines do not require any return lines - but they are

limited (I could be really wrong here, because I do not know much about aircraft

engines). I was recommended to put one in just in case. After much pondering, I

decided to add a fuel return to my right tank. I will certainly look for a fuel

injection engine that does not need a return line. The yellow ties are temporary.

I eventually floxed them in place.

At

this time, I have not looked into the type of engine for my Cozy. I was told that

some fuel injection engines do not require any return lines - but they are

limited (I could be really wrong here, because I do not know much about aircraft

engines). I was recommended to put one in just in case. After much pondering, I

decided to add a fuel return to my right tank. I will certainly look for a fuel

injection engine that does not need a return line. The yellow ties are temporary.

I eventually floxed them in place. [Hindsight]

I eventually ordered my engine with fuel injection that does not require a

return line. Though I can remove it at this time, I decided to plug it at the

firewall. I made a small plug with my lathe. I eventually will seal it with flox

or something.

[Hindsight]

I eventually ordered my engine with fuel injection that does not require a

return line. Though I can remove it at this time, I decided to plug it at the

firewall. I made a small plug with my lathe. I eventually will seal it with flox

or something. I

was rushing through the top and bottom skin and I missed the instruction for

cutting the hole for the fuel drain in the bottom skin. Fortunately I noticed it from reading

other builder's web sites. Since the location of the fuel drain is not very specific in the plan,

I figure as along as it sits over the sump blister, it should be OK.

None-the-less, I centered my fuel drain hole at 4 1/4" forward of the center

section spar face and 1 7/16" from the side of the fuselage. That puts my

fuel drain hole right at the center of the sump blister - to be built later. As I

mentioned, I missed carving a hole in the foam after I have glassed the upper

face of the bottom skin, I have to cut out the glass first, then the foam. I

have one of those circular cutter blades (shown) that I used to lance the glass

layer. Then I used a 1 1/4" hole saw and drilled out the drain hole. I dug

out the remaining glass ring with a blade. Finished the hole with a dowel and

sand paper.

I

was rushing through the top and bottom skin and I missed the instruction for

cutting the hole for the fuel drain in the bottom skin. Fortunately I noticed it from reading

other builder's web sites. Since the location of the fuel drain is not very specific in the plan,

I figure as along as it sits over the sump blister, it should be OK.

None-the-less, I centered my fuel drain hole at 4 1/4" forward of the center

section spar face and 1 7/16" from the side of the fuselage. That puts my

fuel drain hole right at the center of the sump blister - to be built later. As I

mentioned, I missed carving a hole in the foam after I have glassed the upper

face of the bottom skin, I have to cut out the glass first, then the foam. I

have one of those circular cutter blades (shown) that I used to lance the glass

layer. Then I used a 1 1/4" hole saw and drilled out the drain hole. I dug

out the remaining glass ring with a blade. Finished the hole with a dowel and

sand paper.  I

bought my fuel strainer from ACE hardware store as many builders did before me.

It was a bit big but workable. The fuel strainer flange butts against the

fuselage sides and will not sit perfectly centered to the fuel drain hole. My

opportunity came when I went by an Asian supermarket (you have to live in Los

Angeles to find one of those). I found a smaller tea strainer - just a hair larger

than the fuel drain hole. You have to look at the fine print and in Chinese

that says "high quality stainless steel"

I

bought my fuel strainer from ACE hardware store as many builders did before me.

It was a bit big but workable. The fuel strainer flange butts against the

fuselage sides and will not sit perfectly centered to the fuel drain hole. My

opportunity came when I went by an Asian supermarket (you have to live in Los

Angeles to find one of those). I found a smaller tea strainer - just a hair larger

than the fuel drain hole. You have to look at the fine print and in Chinese

that says "high quality stainless steel"  Here's

the picture of the strainer on a scale. As shown, its a hair larger than 2"

in diameter and it will fit over the fuel drain perfectly.

Here's

the picture of the strainer on a scale. As shown, its a hair larger than 2"

in diameter and it will fit over the fuel drain perfectly. According

to the Plan, a dome shape screen is to be secured over the fuel drain hole to the sump. This

screen is to block out larger debris away from the fuel inlet lines (located in

the sump). The problem is that the location of the screen is far from the fuel

cap and its almost impossible to get to (for cleaning), once the fuel tank is

sealed. You may

be able to see the larger debris around the dome shape screen, but you may be

powerless to get to (to clean it out). I am just not too kin about this set up

though no one had any problem with it...

According

to the Plan, a dome shape screen is to be secured over the fuel drain hole to the sump. This

screen is to block out larger debris away from the fuel inlet lines (located in

the sump). The problem is that the location of the screen is far from the fuel

cap and its almost impossible to get to (for cleaning), once the fuel tank is

sealed. You may

be able to see the larger debris around the dome shape screen, but you may be

powerless to get to (to clean it out). I am just not too kin about this set up

though no one had any problem with it... Here's

a picture of my dome shaped screen floxed and glassed in place over my fuel line. It's the same concept as the fuel line strainer that are commonly

used by other aircraft designs. Note the plane is on its upside down position.

Here's

a picture of my dome shaped screen floxed and glassed in place over my fuel line. It's the same concept as the fuel line strainer that are commonly

used by other aircraft designs. Note the plane is on its upside down position. A

builder experienced a leak at this exact location. In

order to safeguard this from happening, I decided to devise some way to squeeze

the hard point against the glass during cure. I

drilled a small hole through the 1/8" NPT plug (note the hole through the

silver color plug to the left of the picture) to allow a small bolt to go

through. Picture

(left) shows the 1"x1"x1/4" hard point, the 1/8" NPT plug

(with a drilled hole), a common bolt and nut and a fuel

drain.

A

builder experienced a leak at this exact location. In

order to safeguard this from happening, I decided to devise some way to squeeze

the hard point against the glass during cure. I

drilled a small hole through the 1/8" NPT plug (note the hole through the

silver color plug to the left of the picture) to allow a small bolt to go

through. Picture

(left) shows the 1"x1"x1/4" hard point, the 1/8" NPT plug

(with a drilled hole), a common bolt and nut and a fuel

drain. Once the hard point is

buried in foam with flox, I slipped the small bolt through the 1/8" plug and hand

tightened the nut. This helped to bring the hard point tight against the

underlying glass, thus squeezing the flox nicely in between to cure.

Once the hard point is

buried in foam with flox, I slipped the small bolt through the 1/8" plug and hand

tightened the nut. This helped to bring the hard point tight against the

underlying glass, thus squeezing the flox nicely in between to cure. Here's

a picture of my fuel drain at the leading edge.

Here's

a picture of my fuel drain at the leading edge.  Here's

a picture on epoxying the viewing glass onto the white back plate.

Here's

a picture on epoxying the viewing glass onto the white back plate.  I

also made a 1 layer glass template around the viewing window of the sight gauge

such that I will have a more defined (cleaner) outline when it is glassed in

place. I have seen some pretty rough looking edges around the sight gauges at

some of the Cozy meets.

I

also made a 1 layer glass template around the viewing window of the sight gauge

such that I will have a more defined (cleaner) outline when it is glassed in

place. I have seen some pretty rough looking edges around the sight gauges at

some of the Cozy meets.  I

did not like cutting the probe with my Dremel (on my trial run) - quite a bit of

vibration and heat build up. I ended up cutting it off with my table top lathe -

resulting in a much cleaner cut with much less heat being generated. Make sure you

do not lose those 'mini' triangular spacers to keep the center probe from

touching the outside tube (housing). I learned from the Cozy forum to pinch the

inner OR the outer tube to keep the 'mini' triangular spacer from slipping out

in time. I chose the easy way by squeezing the inner tube with a pair of pointed

nose pliers. Note the inner tube ends are not round anymore. If you look close,

you can see the 'mini' triangular spacers hidden in the tube ends.

I

did not like cutting the probe with my Dremel (on my trial run) - quite a bit of

vibration and heat build up. I ended up cutting it off with my table top lathe -

resulting in a much cleaner cut with much less heat being generated. Make sure you

do not lose those 'mini' triangular spacers to keep the center probe from

touching the outside tube (housing). I learned from the Cozy forum to pinch the

inner OR the outer tube to keep the 'mini' triangular spacer from slipping out

in time. I chose the easy way by squeezing the inner tube with a pair of pointed

nose pliers. Note the inner tube ends are not round anymore. If you look close,

you can see the 'mini' triangular spacers hidden in the tube ends.  I

made a 1" square 1/4" thick aluminum hard point (with an 1/8" NPT)

for mounting the probes. To make sure I can hide the head of the probes

under the top fairings, I made a 3" and 4" paper template and held it

up against the canopy. Looks like I can hide it even with a 3" radius

fairing.

I

made a 1" square 1/4" thick aluminum hard point (with an 1/8" NPT)

for mounting the probes. To make sure I can hide the head of the probes

under the top fairings, I made a 3" and 4" paper template and held it

up against the canopy. Looks like I can hide it even with a 3" radius

fairing.  I

did not return to the vent lines until I started working on the firewall aft in

Chapter 23. There were many discussion in the Cozy Forum regarding the pros and

cons of the small holes at the back of the vent lines. I decided to leave them

the way it is. In addition, I added a center block (per Buly) to relieve the

tank pressure between the two tanks as well as potential siphoning effect. I

also anchored the vent lines with multiple hose clamps as shown.

I

did not return to the vent lines until I started working on the firewall aft in

Chapter 23. There were many discussion in the Cozy Forum regarding the pros and

cons of the small holes at the back of the vent lines. I decided to leave them

the way it is. In addition, I added a center block (per Buly) to relieve the

tank pressure between the two tanks as well as potential siphoning effect. I

also anchored the vent lines with multiple hose clamps as shown.  Here's

a picture showing the vent line exiting the cowling. I have to drill a 1/4" hole

through the strake lip for the vent line to exit. I also had to cut a small slot

on the cowling to accommodate the same.

Here's

a picture showing the vent line exiting the cowling. I have to drill a 1/4" hole

through the strake lip for the vent line to exit. I also had to cut a small slot

on the cowling to accommodate the same.  Here's

a picture showing the vent line outside the fuselage. Supposedly, the ram air

plays a small part in keeping the fuel from spilling out of the tank when it is

under pressure.

Here's

a picture showing the vent line outside the fuselage. Supposedly, the ram air

plays a small part in keeping the fuel from spilling out of the tank when it is

under pressure.