Before laying out the panel, I must first decide what

instruments I need to support my Cozy mission. Well, I am not sure

![]() .

I plan to fly VFR most of the time, IFR only if I am in a jam, no night flying

(if I can avoid it) and certainly not in IMF conditions. In addition to planned

missions, I wanted to be able to get the instruments - cheap! I started looking

into Cozy flyers' IP and asked a lot of questions. After months of poking

around, I finally ended up with a list of instruments that I am comfortable

with.

.

I plan to fly VFR most of the time, IFR only if I am in a jam, no night flying

(if I can avoid it) and certainly not in IMF conditions. In addition to planned

missions, I wanted to be able to get the instruments - cheap! I started looking

into Cozy flyers' IP and asked a lot of questions. After months of poking

around, I finally ended up with a list of instruments that I am comfortable

with.

Panel Layout

|

Trial and Error with Paper IP

|

|

First Aluminum IP

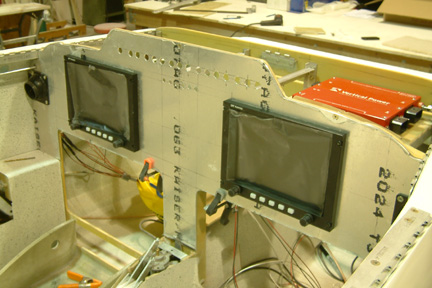

Here's a picture of my first aluminum IP. I used 2024 T3 0.063" thickness. It took considerable amount of trimming and sanding to get it to fit nicely without any interference to the IP cover. |

Here are a few more subsequent trimming and fitting of the aluminum panel onto the glass IP.

|

|

|

|

As shown above, I fitted my GRT HX EFIS to the aluminum panel. I bought the GRT EFIS used, but in really good shape and good price. It came with dual AHRS, and two (2) magnetometers. Note that I started to add angle aluminum (shelf support beams) between the IP and F28. It is because I need additional shelves to mount my Vertical Power (VPX Pro), Skyradar and the dual AHRS. At this time, I have not received my radio stack instruments. I ordered them from SteinAir for the Garmin GTN650, PS Engineering 8000BT, Trig Transponder TT31 and a back up Com radio Garmin 200.

|

One of the requirement is that all instrument/switches

must be identified or labeled. Printed overlay can be so flexible and one can

put unlimited coloring and shading for enhancement. I plan to include a

picture of my control stick and it's switch labels on the panel because I heard

that it was difficult to print lettering onto my infinity stick grip. Note my

first trial with fading color on the overlay |