Preparing the Foam Pieces

I

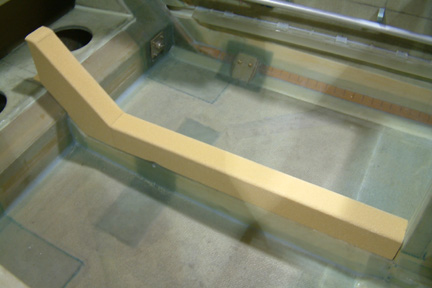

found some left over foam pieces when I built the original heat duct - perfect

I

found some left over foam pieces when I built the original heat duct - perfect![]() .

The foam is 1/4" thick - giving me a bit more room inside the duct. The height of the cover is a bit vague per the drawing in the Plan. I decided to

make mine to 2 1/4" wide and with the 1/4" cover at the top, giving me

a 2 1/2" total height. With 1/2" glass overhang, the total height of

my heat duct cover comes to 3" (as shown in the Plan). The width is exactly

the same as my heat duct below. If

you look close, I have a slight jog at the landing gear bulkhead - thus some

customization is warranted.

.

The foam is 1/4" thick - giving me a bit more room inside the duct. The height of the cover is a bit vague per the drawing in the Plan. I decided to

make mine to 2 1/4" wide and with the 1/4" cover at the top, giving me

a 2 1/2" total height. With 1/2" glass overhang, the total height of

my heat duct cover comes to 3" (as shown in the Plan). The width is exactly

the same as my heat duct below. If

you look close, I have a slight jog at the landing gear bulkhead - thus some

customization is warranted.

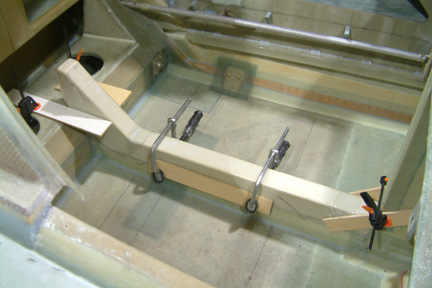

In order to keep the width of the duct consistent throughout its length, I cut a few rectangular foam pieces and fit them inside the trough. Next, I taped down the original heat duct with packing tape for release because the Plans call for a removable heat duct cover.

I

was running out of BID, but I have plenty of UNI on hand. I decided

to use UNI for the heat duct cover. I will add another layer of BID if it turns

out to be too weak. One advantage is that the UNI lays down nicely to the shape

of the heat duct cover. I decided to micro and glass the cover on my work bench

first, then I carefully sat the cover on top of the heat duct (already taped

down with packing tape). I have about 1/2" to 3/4" of glass

overhanging the sides of the heat duct. I clamped down a few wood pieces to make sure

the heat duct cover stayed in place during cure.

I

was running out of BID, but I have plenty of UNI on hand. I decided

to use UNI for the heat duct cover. I will add another layer of BID if it turns

out to be too weak. One advantage is that the UNI lays down nicely to the shape

of the heat duct cover. I decided to micro and glass the cover on my work bench

first, then I carefully sat the cover on top of the heat duct (already taped

down with packing tape). I have about 1/2" to 3/4" of glass

overhanging the sides of the heat duct. I clamped down a few wood pieces to make sure

the heat duct cover stayed in place during cure.