Battery Cover

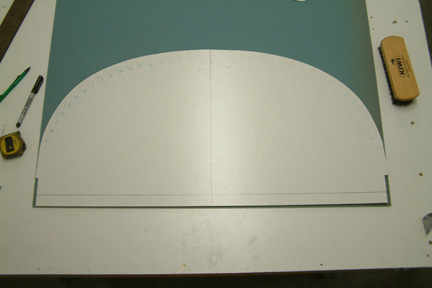

The

exact size and curvature of the battery cover took a bit of effort to determine.

Since the location of the cover is a bit forward of the firewall, it

will be a bit larger than the firewall. However, I can use the firewall

dimension as a rough guide. Fortunately, I still have the wood template

of the firewall from Chapter 6, therefore, I traced out the top edge of the

firewall onto a thin white board (shown left). If you look close, I made a

series of marks (at 1" intervals) radiating from the bottom of the center line

to the top edge of the board. I cut out the template for the next step. I

also added an extra 1" at the bottom for temporary clamping

onto the center section spar.

The

exact size and curvature of the battery cover took a bit of effort to determine.

Since the location of the cover is a bit forward of the firewall, it

will be a bit larger than the firewall. However, I can use the firewall

dimension as a rough guide. Fortunately, I still have the wood template

of the firewall from Chapter 6, therefore, I traced out the top edge of the

firewall onto a thin white board (shown left). If you look close, I made a

series of marks (at 1" intervals) radiating from the bottom of the center line

to the top edge of the board. I cut out the template for the next step. I

also added an extra 1" at the bottom for temporary clamping

onto the center section spar.

I

clamped the white board (template) onto the openings of the center section spar. With a

ruler aligned along the radiating line, I measured the width of the gap between

the roof of the turtle back and the top edge of the template. I took 20

measurements on each side, totaling 40.

I

clamped the white board (template) onto the openings of the center section spar. With a

ruler aligned along the radiating line, I measured the width of the gap between

the roof of the turtle back and the top edge of the template. I took 20

measurements on each side, totaling 40. After

the trial fit, I drew out a half moon shaped paper template (2" width x 1"

height) and traced its outline on all 4 tabs. A bit of trimming and sanding made

it reasonably pleasing. The picture shows the tab at the top of the turtle back.

After

the trial fit, I drew out a half moon shaped paper template (2" width x 1"

height) and traced its outline on all 4 tabs. A bit of trimming and sanding made

it reasonably pleasing. The picture shows the tab at the top of the turtle back. I

was not able to find any instruction in the Plans for the 'loud speaker covers'.

So I used the remaining 1/8" foam and made two covers to fit. Sanding down the

covers to fit took a lot more effort than

expected. Because of the uneven bevel edges of the speaker holes,

I had a

tough time making the covers to sit flush. After 2 1/2 hours of

sanding...fitting...sanding...fitting - they still looked ugly!

I

was not able to find any instruction in the Plans for the 'loud speaker covers'.

So I used the remaining 1/8" foam and made two covers to fit. Sanding down the

covers to fit took a lot more effort than

expected. Because of the uneven bevel edges of the speaker holes,

I had a

tough time making the covers to sit flush. After 2 1/2 hours of

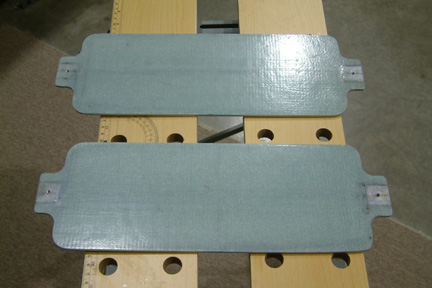

sanding...fitting...sanding...fitting - they still looked ugly! Since

I messed up the right cover, I ended up making a new cover set. At the far ends

of the cover, I embedded a 1" x 1" x 1/8" hard point. Then I

drilled and tapped the hard points. I drilled the 4 holes to accommodate the AN3

bolts at the longitudinal center of the covers,

1/2" from the opening edges. After I tightened the AN3 bolts to the hard

points, I traced out the opening onto the cover, then removed and trimmed to

shape. Here's a picture of my covers.

Since

I messed up the right cover, I ended up making a new cover set. At the far ends

of the cover, I embedded a 1" x 1" x 1/8" hard point. Then I

drilled and tapped the hard points. I drilled the 4 holes to accommodate the AN3

bolts at the longitudinal center of the covers,

1/2" from the opening edges. After I tightened the AN3 bolts to the hard

points, I traced out the opening onto the cover, then removed and trimmed to

shape. Here's a picture of my covers.

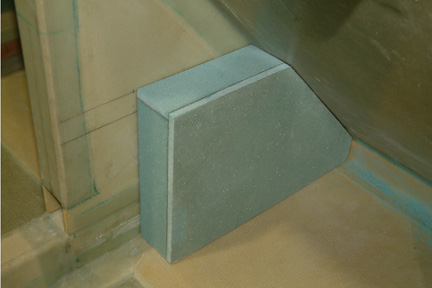

The

landing brake cover consists of 3 sides. Instead of making a

mold out of 1"

foam (per Plan), I used a few pieces of left over foam from the strakes and made

a mock up cover. I have yet to round off the edges before glassing.

The

landing brake cover consists of 3 sides. Instead of making a

mold out of 1"

foam (per Plan), I used a few pieces of left over foam from the strakes and made

a mock up cover. I have yet to round off the edges before glassing. I

carefully sat the brake cover (with 2 layers of BID) back over the landing

brake and wetted out the overhung glass - which is now laying over the packing

tape. I used a couple of sticks to keep the landing brake cover tight against

the fuselage and let it cure over night.

I

carefully sat the brake cover (with 2 layers of BID) back over the landing

brake and wetted out the overhung glass - which is now laying over the packing

tape. I used a couple of sticks to keep the landing brake cover tight against

the fuselage and let it cure over night.  After

curing, I popped the cover off the mock up, trimmed, did a bit of sanding and held

it in place with 4 metal

screws per Plan. I may trim the edges down some more later on...

After

curing, I popped the cover off the mock up, trimmed, did a bit of sanding and held

it in place with 4 metal

screws per Plan. I may trim the edges down some more later on...