Tricks & Methods

This chapter is dedicated to the methods and tricks I used

throughout my Cozy building journey. By no means are these my ideas… in fact,

I learned most of them from builders before me, and friends & neighbors who

contributed their invaluable advice to support my goal. Therefore, I am

documenting them here and hope they can be useful to the next builder. I wanted

to acknowledge and give a BIG THANKS to those who came up with these great ideas

– well, you know who you are!

|

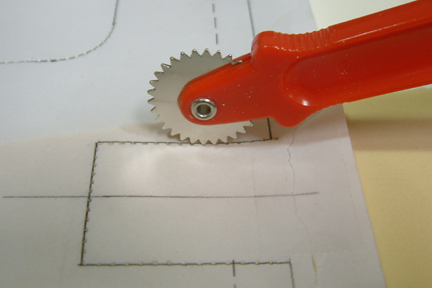

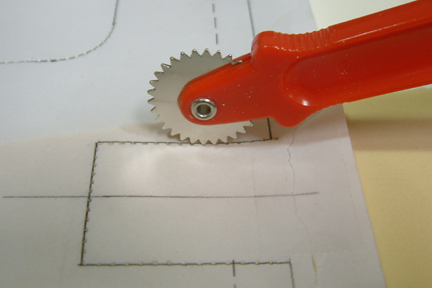

I

transferred the drawings onto the foam using a tracing wheel they use for sewing

(I learned this from the Cozy forum & various web sites). First, I tack the

drawings on the foam with a thumbtack and run the tracing wheel along the lines

of the drawing. The spokes on the wheel put a string of ‘indents’ on the

foam. Surprisingly, the tracing wheel tracks a straight line quite well even in

free hand. Remove the drawings and connects up the dots with a fine felt

tip pen. Though the tracing wheel leaves a bunch of holes on the drawings, they

are readable and can be reused – wonder how I know (hint… you normally

have to re-trace & remake a part if you screw up). Regardless, this

method worked very well! I

transferred the drawings onto the foam using a tracing wheel they use for sewing

(I learned this from the Cozy forum & various web sites). First, I tack the

drawings on the foam with a thumbtack and run the tracing wheel along the lines

of the drawing. The spokes on the wheel put a string of ‘indents’ on the

foam. Surprisingly, the tracing wheel tracks a straight line quite well even in

free hand. Remove the drawings and connects up the dots with a fine felt

tip pen. Though the tracing wheel leaves a bunch of holes on the drawings, they

are readable and can be reused – wonder how I know (hint… you normally

have to re-trace & remake a part if you screw up). Regardless, this

method worked very well!

|

|

I

did not like the inconsistencies of inside rounded corners I made on the I

did not like the inconsistencies of inside rounded corners I made on the Instrument Panel – simply because I do not have that perfect freehand skill

– like a professional carpenter. There's got to be a

better way… I went to a machine shop and had set of angled

templates with round corners made (.125", .25", .5" & .75"

radius respectively). The templates are .25" thick aluminum. With the appropriate

template clamped onto the top of the inside corners of the Instrument Panel, I used

a flush trim router bit and ran it along the edge of the template. I used

˝” diameter bit or smaller – you can find them in most hardware stores or

on the Internet. These templates help shape the foam and fiberglass to a nicely

rounded inside corner every time!

Instrument Panel – simply because I do not have that perfect freehand skill

– like a professional carpenter. There's got to be a

better way… I went to a machine shop and had set of angled

templates with round corners made (.125", .25", .5" & .75"

radius respectively). The templates are .25" thick aluminum. With the appropriate

template clamped onto the top of the inside corners of the Instrument Panel, I used

a flush trim router bit and ran it along the edge of the template. I used

˝” diameter bit or smaller – you can find them in most hardware stores or

on the Internet. These templates help shape the foam and fiberglass to a nicely

rounded inside corner every time!

|

|

One of the

contributors for poor part quality on my parts (discussed in Chapter 4) was due to low

curing temperature (below 70F). Therefore, a heat tent, of sorts, was in order.

Since my Cozy factory is in a large warehouse without heating and cooling and it

would be impractical to heat up the entire warehouse, I needed to find

ways to provide local heating. One of the

contributors for poor part quality on my parts (discussed in Chapter 4) was due to low

curing temperature (below 70F). Therefore, a heat tent, of sorts, was in order.

Since my Cozy factory is in a large warehouse without heating and cooling and it

would be impractical to heat up the entire warehouse, I needed to find

ways to provide local heating.

The local heat tent

is made up of three 4'x8' foam panels (~$10 each). The three panels provide

enough material for a 4'x10'x2' tent (as shown). I also cut up some scrap foam

strips and glued them to the tent corners and joining edges - making the tent 'box'

much more rigid and sturdy for handling.

The heating unit is

made up of two 100 watt light bulbs, a small fan (to circulate the air inside

the heat tent) and an in-line thermostat. Once the tent is in place, I slipped the

heating unit inside the tent and plugged in the power. The heating unit was able to

keep the temperature inside the tent within 80F constantly - just about perfect.

Time will tell if it is worth the effort.

|

|

I read this from

someone's site and followed... I went by Home Depot and picked up several paint

stirrers. They have two sizes - you'll find them both useful. I laid a 8"x11" sand paper

face down and brushed on left-over epoxy on its back. I

then placed the paint stirrers on the epoxied side - butt up against each other.

After cure, I used a razor blade and cut along the edges of the paint stirrers.

You'll end up with sanding sticks for all occasions. I used this to sand down

the heat duct at the aft spacers (Chapter 5). Worked

great!

|

I

started with a rubber squeegee during my practice lay ups and early part of

Chapter 4. I soon got tired of cleaning them - especially when I forget to clean

them by the end of the day. Replacements are somewhat costly in the long run. Then

I started using credit cards instead of the rubber squeegee (I am sure this is

not original). I get a lot of junk ones in the mail all the time, therefore, I

have a constant supply of squeegees for FREE!

Here's

my experience with them:

|

Firstly,

I can wipe the epoxy/micro off the cards easily and if I forget, I just toss them - they are FREE; |

|

Note

that these credit cards comes in different thicknesses. I like the American

Express ones for applying micro onto foam because they are a bit thinner and

tend to bend and slide over the foam nicely (ie. they won't dig into the

foam). On the other hand, I like the Delta Airlines ones better for applying

epoxy on glass because they are a bit firmer; |

|

Sometimes

I trim the credit card into strips for tight places (e.g. applying flox to

round off the acute corner at the base of the front seat back in Chapter 6); |

|

Sometimes

I sharpen or dull the contact edge of the card for rubbing down the peel ply

or plastics. |

Generally,

they worked well for me. You may want to try them out... Just

make sure you use the junk credit cards and not your significant other's  .

As a matter of fact , I think I am going to write a thank you note to American

Express and Delta Airlines for the free squeegees...NOT!

.

As a matter of fact , I think I am going to write a thank you note to American

Express and Delta Airlines for the free squeegees...NOT!

This

is one task I do not wish any builder will have to face. However, if you must,

this is one approach that made my life a bit easier. According to plan, MG-1,

MG-2 and MG-4 need to be floxed in place to support the landing gear shaft. As

I did mine, the MG-1 moved (mysteriously of course) just a bit during cure, such

that the landing gear shaft will not go through.

After

I popped off the MG-1 plate, the bushing was still in tact. To push it out, I

used a knock out punch for the task...

|

A

knock out punch is a tool commonly used in the sheet metal manufacturing

processes for shearing a pre-determined hole (size & shape) in a sheet of metal. It will

provide a nice clean hole compared to using a jig saw or band saw. A knock out

punch consists of a base, a pre-shaped die (i.e. the punch) and a threaded screw

through the center of both components. The punch comes in round, square,

rectangular shapes and in variety of sizes. As you tighten the screw (shown),

the punch will eventually shear a nice clean hole out of the sheet metal. A

knock out punch is a tool commonly used in the sheet metal manufacturing

processes for shearing a pre-determined hole (size & shape) in a sheet of metal. It will

provide a nice clean hole compared to using a jig saw or band saw. A knock out

punch consists of a base, a pre-shaped die (i.e. the punch) and a threaded screw

through the center of both components. The punch comes in round, square,

rectangular shapes and in variety of sizes. As you tighten the screw (shown),

the punch will eventually shear a nice clean hole out of the sheet metal.

|

|

I

used the same idea for pushing the MG-4 bushing out of the LG bulkhead, except I

reversed the orientation of the cutting die (shown). As I tightened the bolt with

a socket wrench, the back of the punch pushed the bushing (nice & flat)

forward until it was flush against the glass. I removed the punch, added a drop of

oil on the exposed bushing that is close to the glass, reversed the punch

direction and worked it back in. By repeating the process a couple times, the

bushing came right

out!!! I

used the same idea for pushing the MG-4 bushing out of the LG bulkhead, except I

reversed the orientation of the cutting die (shown). As I tightened the bolt with

a socket wrench, the back of the punch pushed the bushing (nice & flat)

forward until it was flush against the glass. I removed the punch, added a drop of

oil on the exposed bushing that is close to the glass, reversed the punch

direction and worked it back in. By repeating the process a couple times, the

bushing came right

out!!!

|

Applying

and Smoothing Flox

I

picked up the general approach to this technique from one of many web sites I

read (don't remember who's) before I started building the Cozy. It turned out to be one

of the techniques, that I used often, for making smooth flox fillets. Here's

an example of how I make my flox fillets:

|

I

was applying a flox fillet around an aluminum hard point, but this technique works

on just about any fillet application as called out in the plans. I first

applied DRY flox around the edges of the aluminum hard point. Its a bit lumpy

and does not

have to lay perfect. Just make sure there is an even amount (roughly) along the

fillet edges. I

was applying a flox fillet around an aluminum hard point, but this technique works

on just about any fillet application as called out in the plans. I first

applied DRY flox around the edges of the aluminum hard point. Its a bit lumpy

and does not

have to lay perfect. Just make sure there is an even amount (roughly) along the

fillet edges.

|

|

Right

before I was ready to glass over the hard point, I use a soft brush (or a

brush with longer hair (i.e. >1" or so) and dip it in pure epoxy. Remove

excess epoxy from the brush by sliding it over the edge of epoxy mixing cup as you

always do. Then brush over the DRY flox LIGHTLY. The flox will absorb the epoxy from the brush and 'melts' (smooth) to shape nicely. You'll get the hang of it once you have

done it... Right

before I was ready to glass over the hard point, I use a soft brush (or a

brush with longer hair (i.e. >1" or so) and dip it in pure epoxy. Remove

excess epoxy from the brush by sliding it over the edge of epoxy mixing cup as you

always do. Then brush over the DRY flox LIGHTLY. The flox will absorb the epoxy from the brush and 'melts' (smooth) to shape nicely. You'll get the hang of it once you have

done it...

|

|

Apply

pre-wet glass over the entire hard point and fillet. Touch up the fillets lightly with

the soft brush, to desired perfection. Apply

pre-wet glass over the entire hard point and fillet. Touch up the fillets lightly with

the soft brush, to desired perfection.

|

Fitting

a Small Washer in Tight Space

There

are times that you need to hold a thin washer in really tight spaces such that

you can fit a bolt or rod through it. A good example is in Chapter 12 when

installing the elevators to the canard. There is no room (even for pointed

nose pliers) to hold the washer on its sides nor can you grab onto its flat

surface while trying to push the rod through. Here's how I did it: There

are times that you need to hold a thin washer in really tight spaces such that

you can fit a bolt or rod through it. A good example is in Chapter 12 when

installing the elevators to the canard. There is no room (even for pointed

nose pliers) to hold the washer on its sides nor can you grab onto its flat

surface while trying to push the rod through. Here's how I did it:

I

used a small piece of masking tape and stuck it to the edge of the washer - now,

the washer is dangling by its edge. Lower the washer in the slot, stick the bolt

or rod through the center hole of the washer, pull off the masking tape and you

are done. Its simple and works great!

|

Brushes,

Re-use Or Not-Re-Use

You

will find many discussion in the archives regarding re-use or not-re-use of the

brushes. I always felt that brushes are cheap, especially when you wait for a

sale from Harbor Freight and stock up. I used it once and tossed, no cleaning, no

mess... Besides, I tried to clean the brushes a couple of times and can never

re-use them because they stiffed up like a chisel afterwards.

I

got a chance to talk to Paul Stowitts (who prefers to re-use his brushes) a while

back and picked up some of his cleaning techniques. I then realized I missed a

couple of cleaning steps... A bit later, I included those missing steps and to

my surprise, it worked very well. The brushes stayed softer than new ones and NO

loose hair ever again - I like it!

|

Here's

what I did for cleaning and preparing the brushes for re-use:

Step

1 - After

use, I squeezed out the residue epoxy with a paper towel (those 1/2 sheet ones or

whatever I can get my hands on). I normally squeezed it about 3-5 times, using

the same paper towel.

|

|

Step

2 - I soaked a new paper towel (those 1/2 sheet ones) with Acetone and wrapped the wetted

part over the used brush. Step

2 - I soaked a new paper towel (those 1/2 sheet ones) with Acetone and wrapped the wetted

part over the used brush.

|

|

Step

3 - I tucked the whole thing inside a sandwich bag and wrapped it tight around itself. Step

3 - I tucked the whole thing inside a sandwich bag and wrapped it tight around itself.

|

|

Step

4 - I squeezed the brush part between a vise or some weight. BTW, you do not have to

kill it with the vise. Step

4 - I squeezed the brush part between a vise or some weight. BTW, you do not have to

kill it with the vise.

The

next time you need a brush, just take it out of the vise and unwrap the plastic.

I like it, not because of cost reasons. It turned out to be a much softer and

smoother brush and works better than new ones. As I mentioned, no loose hair

either.

|

There

are times I need to drill a hole vertically through a cylindrical part, such as

a tube (Chapter 16) or a bolt (Chapter 13). For one reason or another, the

V-block was not handy, the part was too small or the hole just did not need to

be THAT perfect - one of those quick tasks... Here's what I do...

|

As

shown (left), I was drilling a hole through a AN3 bolt for a cotter pin. I first

clamp down the bolt in a vise and place it under my drill press. Then I lower

the drill bit against the top of the body of the bolt. Then I slip a razor blade

(or a straight metal ruler) between the tool tip and the bolt body. If the blade

is level, the drill bit is dead center to the apex of the bolt. On the other

hand, if the blade is tilted, you are off center. Move the vise (with the bolt)

a bit until the blade is level. A simple, but very effective

technique. As

shown (left), I was drilling a hole through a AN3 bolt for a cotter pin. I first

clamp down the bolt in a vise and place it under my drill press. Then I lower

the drill bit against the top of the body of the bolt. Then I slip a razor blade

(or a straight metal ruler) between the tool tip and the bolt body. If the blade

is level, the drill bit is dead center to the apex of the bolt. On the other

hand, if the blade is tilted, you are off center. Move the vise (with the bolt)

a bit until the blade is level. A simple, but very effective

technique.

|

Center

Section Spar & Wing Match Drilling Bit

To

use this Tool set, you must have an access hole on the under side of the Center

Section Spar (per plan). In addition, you are given the locations of the wing

bolts in Chapter 14 Page 5. I drilled a 1/4" hole at each of those

locations (i.e. Aft face of the center section spar). Then I transfer a matching

set of these 1/4" alignment holes onto the forward face of the center

center spar. Note that the FF alignment hole does not have the same BL location

as the AF ones (hint: look for the 2.02" dimension). These

alignment holes were intended as a guide for drilling the matching hole between

the Center Section Spar and Wing hard points such that the bolts comes out

perpendicularly to the aft face of the center section spar. Once you have the wing and center

section spar lined up and secured, then this Match Drilling Bit will come in handy as

follows...

|

The

Match Drilling Tool set comes in 2 parts - the funny looking (customized) drill

bit and the 1/4" drill attachment rod. The

Match Drilling Tool set comes in 2 parts - the funny looking (customized) drill

bit and the 1/4" drill attachment rod.

|

|

I

used an collapsible magnet to hold the Drill Bit and stick it through the access

hole at the under side of the Center Section Spar. Then I maneuver the drill tip

through the 1/4" alignment hole at the aft face of the Center Section Spar. I

used an collapsible magnet to hold the Drill Bit and stick it through the access

hole at the under side of the Center Section Spar. Then I maneuver the drill tip

through the 1/4" alignment hole at the aft face of the Center Section Spar.

|

|

Then

I feed the 1/4" drill attachment rod through the 1/4" alignment hole

(at the forward face of the Center Section Spar) and into the back end of the

Drill Bit. Now the Drill Bit is hanging between the two 1/4" alignment

holes of the Center Section Spar. Pull out the magnet. Then

I feed the 1/4" drill attachment rod through the 1/4" alignment hole

(at the forward face of the Center Section Spar) and into the back end of the

Drill Bit. Now the Drill Bit is hanging between the two 1/4" alignment

holes of the Center Section Spar. Pull out the magnet.

|

|

Carefully

rotate the 1/4" drill attachment rod such that its flat face sits against

either one of the 2 set screws. Use an extended Allen bit (as shown) and tighten the set

screw. Attached a hand drill to the end of the drill attachment rod and start

drilling. Carefully

rotate the 1/4" drill attachment rod such that its flat face sits against

either one of the 2 set screws. Use an extended Allen bit (as shown) and tighten the set

screw. Attached a hand drill to the end of the drill attachment rod and start

drilling.

|

It is important to note that a more powerful drill works much better.

I used a DeWalt 7.8A drill instead of my other Skill 3.5A electric drill. It cut

down my drilling time by 75%. It may be a good idea to make a trial run on a scrap

piece of aluminum - just to get a feel for the Tool

before going for the real thing!

I

transferred the drawings onto the foam using a tracing wheel they use for sewing

(I learned this from the Cozy forum & various web sites). First, I tack the

drawings on the foam with a thumbtack and run the tracing wheel along the lines

of the drawing. The spokes on the wheel put a string of ‘indents’ on the

foam. Surprisingly, the tracing wheel tracks a straight line quite well even in

free hand. Remove the drawings and connects up the dots with a fine felt

tip pen. Though the tracing wheel leaves a bunch of holes on the drawings, they

are readable and can be reused – wonder how I know (hint… you normally

have to re-trace & remake a part if you screw up). Regardless, this

method worked very well!

I

transferred the drawings onto the foam using a tracing wheel they use for sewing

(I learned this from the Cozy forum & various web sites). First, I tack the

drawings on the foam with a thumbtack and run the tracing wheel along the lines

of the drawing. The spokes on the wheel put a string of ‘indents’ on the

foam. Surprisingly, the tracing wheel tracks a straight line quite well even in

free hand. Remove the drawings and connects up the dots with a fine felt

tip pen. Though the tracing wheel leaves a bunch of holes on the drawings, they

are readable and can be reused – wonder how I know (hint… you normally

have to re-trace & remake a part if you screw up). Regardless, this

method worked very well! I

did not like the inconsistencies of inside rounded corners I made on the

I

did not like the inconsistencies of inside rounded corners I made on the Instrument Panel – simply because I do not have that perfect freehand skill

– like a professional carpenter. There's got to be a

better way… I went to a machine shop and had set of angled

templates with round corners made (.125", .25", .5" & .75"

radius respectively). The templates are .25" thick aluminum. With the appropriate

template clamped onto the top of the inside corners of the Instrument Panel, I used

a flush trim router bit and ran it along the edge of the template. I used

˝” diameter bit or smaller – you can find them in most hardware stores or

on the Internet. These templates help shape the foam and fiberglass to a nicely

rounded inside corner every time!

Instrument Panel – simply because I do not have that perfect freehand skill

– like a professional carpenter. There's got to be a

better way… I went to a machine shop and had set of angled

templates with round corners made (.125", .25", .5" & .75"

radius respectively). The templates are .25" thick aluminum. With the appropriate

template clamped onto the top of the inside corners of the Instrument Panel, I used

a flush trim router bit and ran it along the edge of the template. I used

˝” diameter bit or smaller – you can find them in most hardware stores or

on the Internet. These templates help shape the foam and fiberglass to a nicely

rounded inside corner every time!

One of the

contributors for poor part quality on my parts (discussed in Chapter 4) was due to low

curing temperature (below 70F). Therefore, a heat tent, of sorts, was in order.

Since my Cozy factory is in a large warehouse without heating and cooling and it

would be impractical to heat up the entire warehouse, I needed to find

ways to provide local heating.

One of the

contributors for poor part quality on my parts (discussed in Chapter 4) was due to low

curing temperature (below 70F). Therefore, a heat tent, of sorts, was in order.

Since my Cozy factory is in a large warehouse without heating and cooling and it

would be impractical to heat up the entire warehouse, I needed to find

ways to provide local heating.

A

knock out punch is a tool commonly used in the sheet metal manufacturing

processes for shearing a pre-determined hole (size & shape) in a sheet of metal. It will

provide a nice clean hole compared to using a jig saw or band saw. A knock out

punch consists of a base, a pre-shaped die (i.e. the punch) and a threaded screw

through the center of both components. The punch comes in round, square,

rectangular shapes and in variety of sizes. As you tighten the screw (shown),

the punch will eventually shear a nice clean hole out of the sheet metal.

A

knock out punch is a tool commonly used in the sheet metal manufacturing

processes for shearing a pre-determined hole (size & shape) in a sheet of metal. It will

provide a nice clean hole compared to using a jig saw or band saw. A knock out

punch consists of a base, a pre-shaped die (i.e. the punch) and a threaded screw

through the center of both components. The punch comes in round, square,

rectangular shapes and in variety of sizes. As you tighten the screw (shown),

the punch will eventually shear a nice clean hole out of the sheet metal. I

used the same idea for pushing the MG-4 bushing out of the LG bulkhead, except I

reversed the orientation of the cutting die (shown). As I tightened the bolt with

a socket wrench, the back of the punch pushed the bushing (nice & flat)

forward until it was flush against the glass. I removed the punch, added a drop of

oil on the exposed bushing that is close to the glass, reversed the punch

direction and worked it back in. By repeating the process a couple times, the

bushing came right

out!!!

I

used the same idea for pushing the MG-4 bushing out of the LG bulkhead, except I

reversed the orientation of the cutting die (shown). As I tightened the bolt with

a socket wrench, the back of the punch pushed the bushing (nice & flat)

forward until it was flush against the glass. I removed the punch, added a drop of

oil on the exposed bushing that is close to the glass, reversed the punch

direction and worked it back in. By repeating the process a couple times, the

bushing came right

out!!!  I

was applying a flox fillet around an aluminum hard point, but this technique works

on just about any fillet application as called out in the plans. I first

applied DRY flox around the edges of the aluminum hard point. Its a bit lumpy

and does not

have to lay perfect. Just make sure there is an even amount (roughly) along the

fillet edges.

I

was applying a flox fillet around an aluminum hard point, but this technique works

on just about any fillet application as called out in the plans. I first

applied DRY flox around the edges of the aluminum hard point. Its a bit lumpy

and does not

have to lay perfect. Just make sure there is an even amount (roughly) along the

fillet edges. Right

before I was ready to glass over the hard point, I use a soft brush (or a

brush with longer hair (i.e. >1" or so) and dip it in pure epoxy. Remove

excess epoxy from the brush by sliding it over the edge of epoxy mixing cup as you

always do. Then brush over the DRY flox LIGHTLY. The flox will absorb the epoxy from the brush and 'melts' (smooth) to shape nicely. You'll get the hang of it once you have

done it...

Right

before I was ready to glass over the hard point, I use a soft brush (or a

brush with longer hair (i.e. >1" or so) and dip it in pure epoxy. Remove

excess epoxy from the brush by sliding it over the edge of epoxy mixing cup as you

always do. Then brush over the DRY flox LIGHTLY. The flox will absorb the epoxy from the brush and 'melts' (smooth) to shape nicely. You'll get the hang of it once you have

done it... Apply

pre-wet glass over the entire hard point and fillet. Touch up the fillets lightly with

the soft brush, to desired perfection.

Apply

pre-wet glass over the entire hard point and fillet. Touch up the fillets lightly with

the soft brush, to desired perfection.  There

are times that you need to hold a thin washer in really tight spaces such that

you can fit a bolt or rod through it. A good example is in Chapter 12 when

installing the elevators to the canard. There is no room (even for pointed

nose pliers) to hold the washer on its sides nor can you grab onto its flat

surface while trying to push the rod through. Here's how I did it:

There

are times that you need to hold a thin washer in really tight spaces such that

you can fit a bolt or rod through it. A good example is in Chapter 12 when

installing the elevators to the canard. There is no room (even for pointed

nose pliers) to hold the washer on its sides nor can you grab onto its flat

surface while trying to push the rod through. Here's how I did it:

Step

2 - I soaked a new paper towel (those 1/2 sheet ones) with Acetone and wrapped the wetted

part over the used brush.

Step

2 - I soaked a new paper towel (those 1/2 sheet ones) with Acetone and wrapped the wetted

part over the used brush. Step

3 - I tucked the whole thing inside a sandwich bag and wrapped it tight around itself.

Step

3 - I tucked the whole thing inside a sandwich bag and wrapped it tight around itself. Step

4 - I squeezed the brush part between a vise or some weight. BTW, you do not have to

kill it with the vise.

Step

4 - I squeezed the brush part between a vise or some weight. BTW, you do not have to

kill it with the vise. As

shown (left), I was drilling a hole through a AN3 bolt for a cotter pin. I first

clamp down the bolt in a vise and place it under my drill press. Then I lower

the drill bit against the top of the body of the bolt. Then I slip a razor blade

(or a straight metal ruler) between the tool tip and the bolt body. If the blade

is level, the drill bit is dead center to the apex of the bolt. On the other

hand, if the blade is tilted, you are off center. Move the vise (with the bolt)

a bit until the blade is level. A simple, but very effective

technique.

As

shown (left), I was drilling a hole through a AN3 bolt for a cotter pin. I first

clamp down the bolt in a vise and place it under my drill press. Then I lower

the drill bit against the top of the body of the bolt. Then I slip a razor blade

(or a straight metal ruler) between the tool tip and the bolt body. If the blade

is level, the drill bit is dead center to the apex of the bolt. On the other

hand, if the blade is tilted, you are off center. Move the vise (with the bolt)

a bit until the blade is level. A simple, but very effective

technique.  The

Match Drilling Tool set comes in 2 parts - the funny looking (customized) drill

bit and the 1/4" drill attachment rod.

The

Match Drilling Tool set comes in 2 parts - the funny looking (customized) drill

bit and the 1/4" drill attachment rod. I

used an collapsible magnet to hold the Drill Bit and stick it through the access

hole at the under side of the Center Section Spar. Then I maneuver the drill tip

through the 1/4" alignment hole at the aft face of the Center Section Spar.

I

used an collapsible magnet to hold the Drill Bit and stick it through the access

hole at the under side of the Center Section Spar. Then I maneuver the drill tip

through the 1/4" alignment hole at the aft face of the Center Section Spar. Then

I feed the 1/4" drill attachment rod through the 1/4" alignment hole

(at the forward face of the Center Section Spar) and into the back end of the

Drill Bit. Now the Drill Bit is hanging between the two 1/4" alignment

holes of the Center Section Spar. Pull out the magnet.

Then

I feed the 1/4" drill attachment rod through the 1/4" alignment hole

(at the forward face of the Center Section Spar) and into the back end of the

Drill Bit. Now the Drill Bit is hanging between the two 1/4" alignment

holes of the Center Section Spar. Pull out the magnet. Carefully

rotate the 1/4" drill attachment rod such that its flat face sits against

either one of the 2 set screws. Use an extended Allen bit (as shown) and tighten the set

screw. Attached a hand drill to the end of the drill attachment rod and start

drilling.

Carefully

rotate the 1/4" drill attachment rod such that its flat face sits against

either one of the 2 set screws. Use an extended Allen bit (as shown) and tighten the set

screw. Attached a hand drill to the end of the drill attachment rod and start

drilling.