Alignment

Pin with Removable Bolts

The

canard alignment pin per plan is anchored in place and is not removable.

According to Cozy Forum FAQ, this approach made it hard to remove the canard. It

suggests an alternative approach that allows the pin to be removed as needed.

Surprisingly, I was not able to find any pictures on this approach

from any builder's sites. Regardless, I decided to take the removable bolt

approach. Here's what I did...

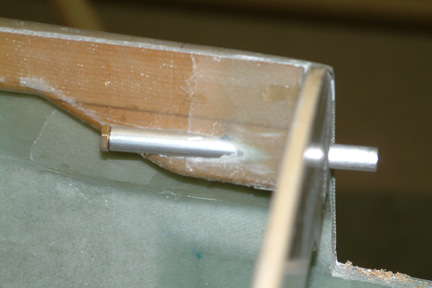

I

bought 8 feet of aluminum tubing with 3/8" OD from McMaster Carr (they did

not have anything shorter) - it

has the same diameter as its facing insert (CN-2) called out in the plans. I

cut two 4" lengths of tube with my band saw. The tubing has a small ID

(I was not

able to find any with 3/8" OD and 3/16" ID), therefore, I have to ream

out the ID to accommodate the AN-3 bolt diameter called out per plan.

In

this chapter, we will fit the canard to the fuselage, aligning it so that it is

level, perpendicular to the longitudinal axis of the fuselage in plan view, and

with the airfoil at the correct angle of incidence. This chapter is divided into

three sections:

In

this chapter, we will fit the canard to the fuselage, aligning it so that it is

level, perpendicular to the longitudinal axis of the fuselage in plan view, and

with the airfoil at the correct angle of incidence. This chapter is divided into

three sections: At

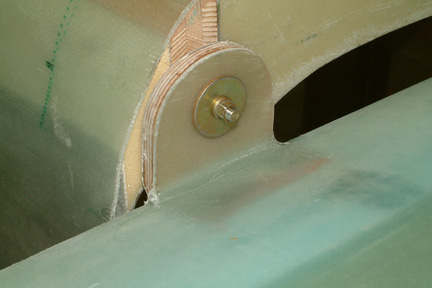

the center of the longeron doublers, I put a 3/8" hole straight through -

making sure the holes are parallel with the longitudinal axis of the fuselage

and horizontal as well. Due to the curvature of the longerons and doublers, the

drill bit will protrude out of the sides of the doublers. That's OK, because I

will eventually cover them up with glass. I slipped the 4" tubes through

the straight holes.

At

the center of the longeron doublers, I put a 3/8" hole straight through -

making sure the holes are parallel with the longitudinal axis of the fuselage

and horizontal as well. Due to the curvature of the longerons and doublers, the

drill bit will protrude out of the sides of the doublers. That's OK, because I

will eventually cover them up with glass. I slipped the 4" tubes through

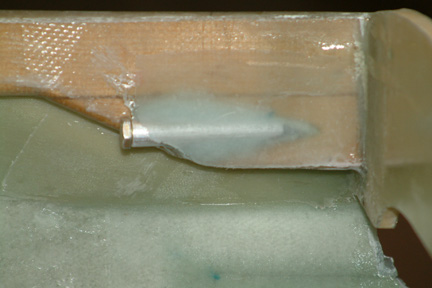

the straight holes.  With

the longer bolt, I have two choices - I can push the bolt through the alignment

hole from fore to aft OR from aft forward. They both worked - just personal

preference.

With

the longer bolt, I have two choices - I can push the bolt through the alignment

hole from fore to aft OR from aft forward. They both worked - just personal

preference.