Procedure to Slide Steel Rod to Attach

Elevator

I removed the canard elevators several for fill and prime

in Chapter 25. Its time to put it back - well not so quick. There are three

simple tricks that can help to slide the steel rods back a bit easier...

1) Use a sliver of masking tape and attach to the edge of

the washer. This way, you can hold the washer in place while sliding the steel

rod through. Refer to the trick Fitting a small washer in

Tight Space.

2) Once you inserted the steel rods through the outboard

holes, it starts to droop down (inside the elevators). Now, you'll have a hard

time getting it through the second and the third holes. I removed the elevators

and re-insert the steel rods (without the elevators) to confirm which direction

the rods are drooping. It becomes obvious once you get a chance to see it.

Here's the trick - once you got the steel rod in the first

hole, turn the canard right side up. The steel rod will find it's way to the

middle and third hole - pure magic!

3) Grab the end of the steel rod with a vice grip (or hand

drill) and turn the steel rod slowly while feeding it in. Life is good again!

I

trimmed the inboard ends of the elevators till I got 1/8" clearance when

the elevators are in the full trailing down position. Since the gap is tight

against the fuselage, I have to move the canard off and on the fuselage between

sanding - total about 10 times and it is getting heavier every time.

I

trimmed the inboard ends of the elevators till I got 1/8" clearance when

the elevators are in the full trailing down position. Since the gap is tight

against the fuselage, I have to move the canard off and on the fuselage between

sanding - total about 10 times and it is getting heavier every time. It

has been reported that the offset control arm nut tends to get loose occasionally.

This is especially inconvenient after the inboard ends of the elevator are

sealed off. In addition, there are times this nut needs to be removed for fine

adjustment later on. Besides, I need to plug up the access hole before glassing

the inboard end of the elevators. Note the bolt and regular nut.

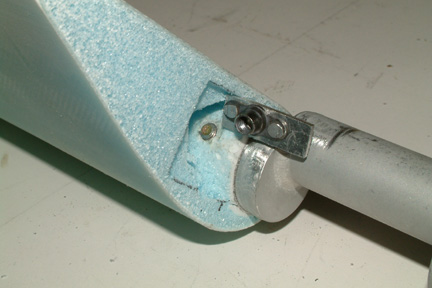

It

has been reported that the offset control arm nut tends to get loose occasionally.

This is especially inconvenient after the inboard ends of the elevator are

sealed off. In addition, there are times this nut needs to be removed for fine

adjustment later on. Besides, I need to plug up the access hole before glassing

the inboard end of the elevators. Note the bolt and regular nut. To

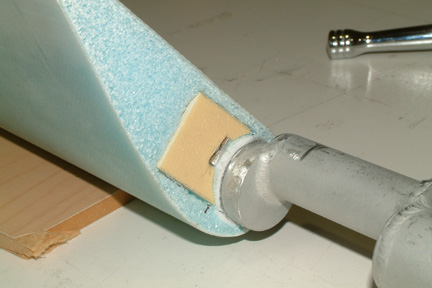

seal off the access hole, I shaped a small cover with Clark foam. However, I

need access to the nut behind the cover later. So I made a crude wrench out of

1/16" aluminum and drilled out a couple small slots on the foam cover.

To

seal off the access hole, I shaped a small cover with Clark foam. However, I

need access to the nut behind the cover later. So I made a crude wrench out of

1/16" aluminum and drilled out a couple small slots on the foam cover. I

figure, if I need to get to the nut after the inboard of the elevator is glassed in, all I need

to do is to drill out those two little slots, stick the wrench in, tighten the

bolt, then seal those little holes back with just about anything (like 5-min

epoxy, hot glue etc.) and nobody can see... so far so good.

I

figure, if I need to get to the nut after the inboard of the elevator is glassed in, all I need

to do is to drill out those two little slots, stick the wrench in, tighten the

bolt, then seal those little holes back with just about anything (like 5-min

epoxy, hot glue etc.) and nobody can see... so far so good. I

posted the question to Wayne Hicks and he suggested a nut plate. Ahhh... that

made sense, but how do I rivet the nut plate onto the tube at this point?

I

posted the question to Wayne Hicks and he suggested a nut plate. Ahhh... that

made sense, but how do I rivet the nut plate onto the tube at this point?  Once

I tightened the bolt to the new nut plate, I floxed the aluminum tab in place

(inside the access hole).

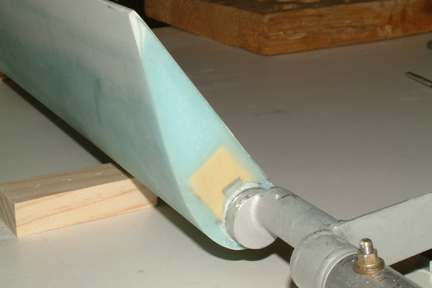

Once

I tightened the bolt to the new nut plate, I floxed the aluminum tab in place

(inside the access hole).  I fitted the foam cover in place and added more flox

to the tab ends (of the foam) and around the foam cover. Then I glassed the

whole inboard end of the elevator.

I fitted the foam cover in place and added more flox

to the tab ends (of the foam) and around the foam cover. Then I glassed the

whole inboard end of the elevator.

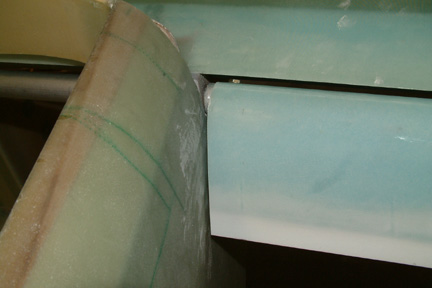

After

all the alignment on the canard was completed, I have a very small gap between

the fuselage edges and the bottom of the canard. I can probably slide 2 maybe 3

sheets of paper between them. In addition, the gap is not uniform throughout. So if

I follow the plan and install 1 ply of glass, I may still end up with a gap

somewhere. I decided to use flox as a filler. It worked out nicely - no gap and no

seam. Don't

forget to lay down packing tape onto the bottom of the canard or it will give

you a really, really bad day when you have to remove the canard!

After

all the alignment on the canard was completed, I have a very small gap between

the fuselage edges and the bottom of the canard. I can probably slide 2 maybe 3

sheets of paper between them. In addition, the gap is not uniform throughout. So if

I follow the plan and install 1 ply of glass, I may still end up with a gap

somewhere. I decided to use flox as a filler. It worked out nicely - no gap and no

seam. Don't

forget to lay down packing tape onto the bottom of the canard or it will give

you a really, really bad day when you have to remove the canard!